KINGREAL STEEL SLITTER 1300MM Economical Sheet Slitting Machine is designed for processing thin coils with a thickness of 0.2-2.0mm, providing customers with narrow strips with high precision.

KINGREAL STEEL SLITTER has more than 20 years of experience in manufacturing and selling metal coil slitting machine to Russia, India, Indonesia, Turkey, Saudi Arabia and Brazil.

Customers on a tighter budget can purchase an economical coil slitting machine from KINGREAL STEEL SLITTER. The primary function of the economical metal coil slitting line is to cut large coils into the precise smaller coil strips that clients need, and then rewind the production line.

Compared to standard metal slitting machines, this economical coil slitting machine can still precisely slit a variety of metal materials, such as stainless steel, aluminum, and copper, producing highly consistent narrow strips.

According to customer specifications, KINGREAL STEEL SLITTER can provide 1300MM Economical Coil Slitting Machine with various features and cost-effectiveness. Broader coils can generally be accurately cut only on metal slitting machines that are quite large in scale. As a result, the associated location and expense will be high.

This Simple Coil Slitting Machine is design to incoming wide strip rolls cutting edge, longitudinal cutting into set size of narrow strip rolls, and can be large rolls slitting into small rolls. (Thickness: 0.2-2.0mm; Width: 1300MM)

Hydraulic Decoiler -- Pinch Roller -- Loop Bridge For Pit -- Side Guide Pinch Roller -- Slitter Head -- Edge Coil Winder -- Separator -- Hydraulic Rewinder

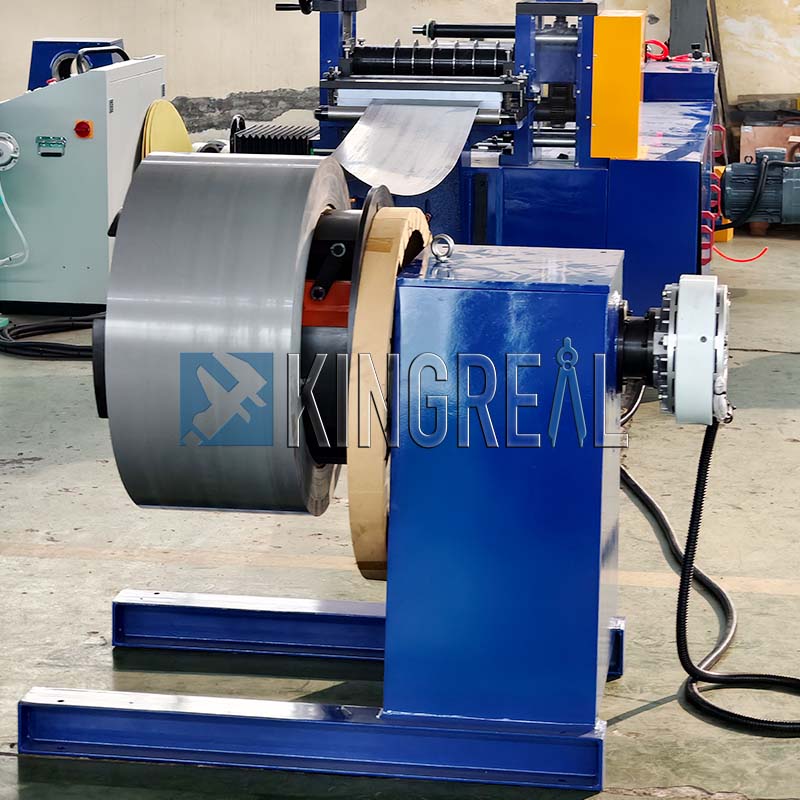

①Hydraulic Uncoiler (with auxiliary support), used to support the coil plate and provide tension to the steel strip, consists of frame, spindle, rising and shrinking reel, unwinding and pressing device, braking device, auxiliary support, and power part.

②Guide side guide position, The strip edge correctly positioned into the knife axis and centering role, to ensure that the slitting of the strip after the slitting kerf will not produce a snake or sickle bend is mainly composed of the side guide position, the pressure material to the rollers, the short transition bridge. Ensure that the strip enters the front loop sleeve correctly and quickly

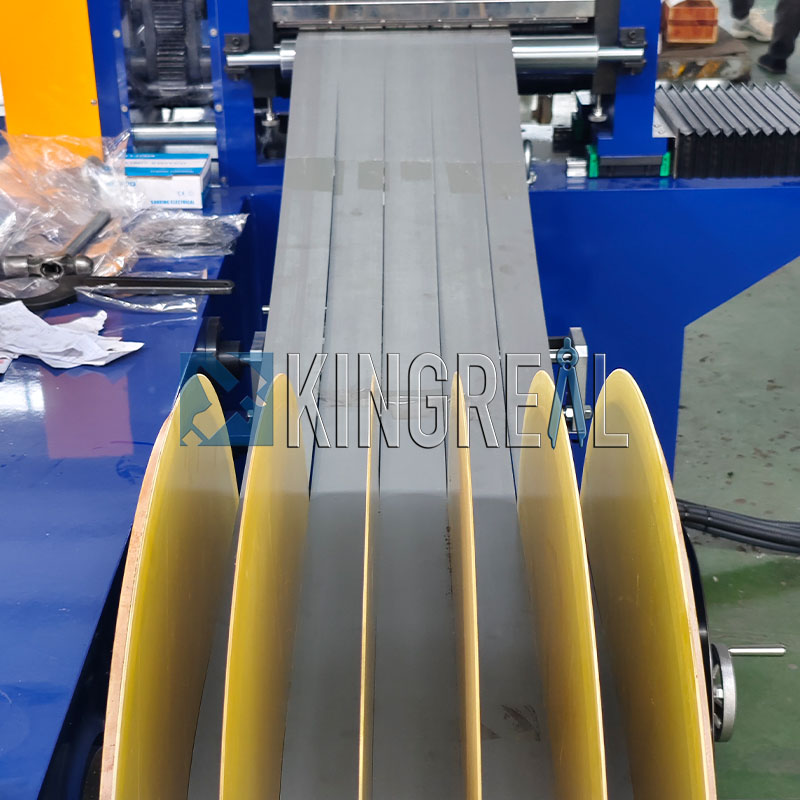

③Slitting Machine

Rolling and shearing the incoming steel strip into narrow strip to meet the customer's requirements, consisting of frame, knife shaft, knife shaft plaque, synchronized lifting device, power system.

|

(A) Steel coil raw material parameters |

|

|

Applicable materials |

general steel coil; galvanized coil |

|

Thickness of steel plate |

0.2mm ~ 2.0mm |

|

Width of steel plate |

500mm ~ 1250mm |

|

Inside diameter of steel coil |

Φ508mm |

|

Outer diameter of steel coil |

Φ1800mm |

|

Weight of steel coil |

≤10 tons |

|

(B) Parameters of slitting finished products |

|

|

Width tolerance |

≤±0.02mm |

|

Straightness of longitudinal shear |

≤1mm/2000mm |

|

Diameter of positive circle of winder |

Φ508mm |

|

Outer diameter of coiling machine |

≤Φ1800mm |

|

|

|

|

KINGREAL STEEL SLITTER offers a comprehensive range of after-sales services, including economical coil slitting machine installation, operating instructions, and routine maintenance. KINGREAL STEEL SLITTER experienced engineers have traveled to numerous countries, including the United States, Brazil, Mexico, Qatar, and Russia, to assist customers with after-sales issues. If an economical coil slitting machine component experiences wear and tear, KINGREAL STEEL SLITTER will promptly provide the corresponding spare part. |

|

Yes, KINGREAL STEEL SLITTER is a professional metal coil slitting machines manufacturer, we are an OEM.

KINGREAL STEEL SLITTER have been focusing on the field of machine manufacturing for more than 20 years.

There are 2 ways: either by plane or by train to Foshan/Guangzhou port. KINGREAL STEEL SLITTER will be picking you up in plane/train station, then we can go together.

40% deposit is paid before production, the balance paid after inspection confirmation before shipment.

If buyers come to our factory to inspect, the training to install and operate is provided face to face.

If not, Manual book and video is provided to show how to install and operate.

Yes KINGREAL STEEL SLITTER can, we use iron wire for fixing machines in container, also small wood pads to hold machines tight and don't move around during shipment.