Slitter rewinding machine For Stainless Steel Don't hesitate to contact us for an up-to-date quote! KINGREAL as a professional coil process equipment supplier in China, has over 20 years experiences on manufacturing and trade. We can provide high quality slitter rewinding machine for stainless steel.

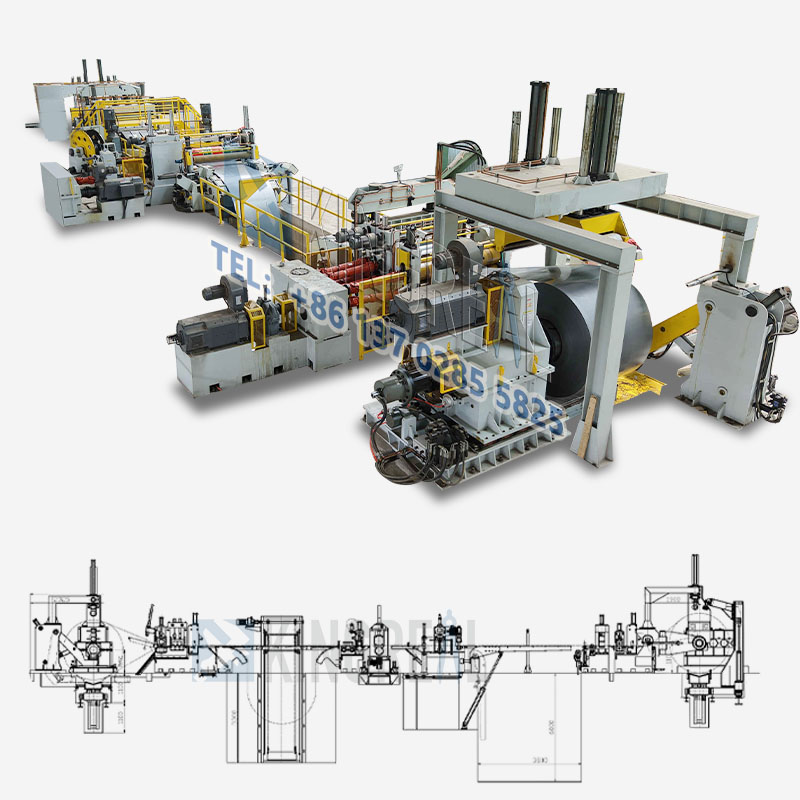

KINGREAL SLITTER stainless steel slitting line is main consists of decoiler, steel slitting machine and rewinder. At the same time, the different components are designed according to the characteristics of stainless steel.

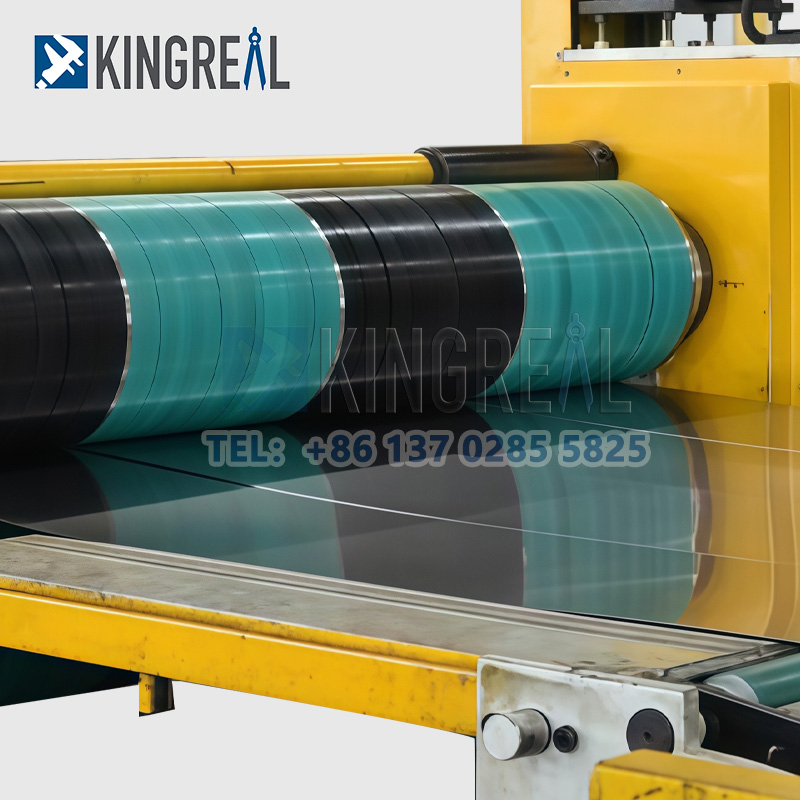

The stainless steel material coil can be cut into strips of the same width using the stainless steel slitting line, and these strips can then be rolled up based on the needs of the customer.

As a manufacturer of web processing equipment for more than 20 years, KINGREAL STEEL SLITTER can guarantee the accuracy and high speed production efficiency of the stainless steel slitting machine due to their extensive production expertise in coil slitting lines. The ability to precisely slit stainless steel coil into various widths, along with high quality production components and precise cutting equipment, are essential to the success of production.

1. Raw Material Specification:

|

Max Coil Weight |

15T |

|

Min Slitter Width |

21mm |

|

Max Slitter Strip |

20 |

|

Accuracy |

≤0.05mm |

|

Burs |

≤0.03mm |

2. Stainless Steel Slitting Production Line Parameters:

|

Material |

Stainless Steel Or Other |

|

Thickness Range |

0.3-2.5mm |

|

Width Range |

500-1800mm |

|

O.D. |

≤φ2000mm |

|

MaximumSlitting Speed |

220m/min |

|

Maximum Slit |

35pcs |

|

Maximum Belt Speed |

20m/min |

|

Capacity |

258KW |

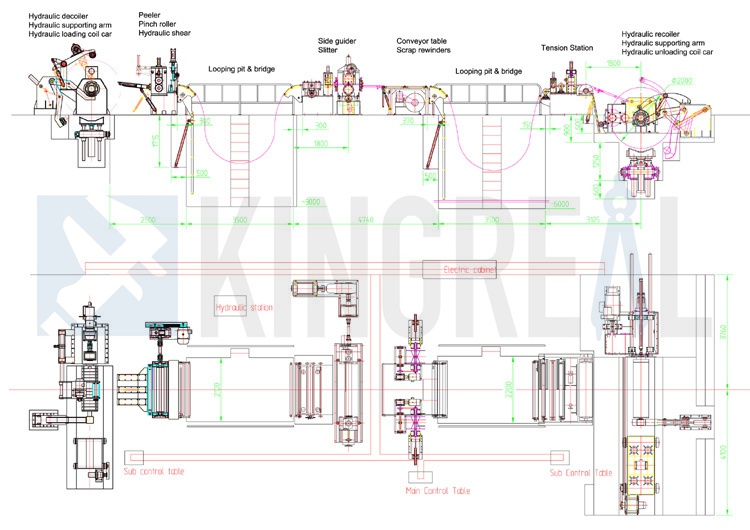

3.Main Components List:

|

Name |

Lis |

|

Hydraulic coil-loading car |

1 |

|

Cantilever-mandrelDecoiler |

1 |

|

Double-roller pinch feeder & Five-roller Leveler and Shear |

1 |

|

Pit Loop |

2 |

|

Side Guide |

1 |

|

Slitting Machine |

1 |

|

Scrap reeling |

1 |

|

Pre-separator And Tensioner |

1 |

|

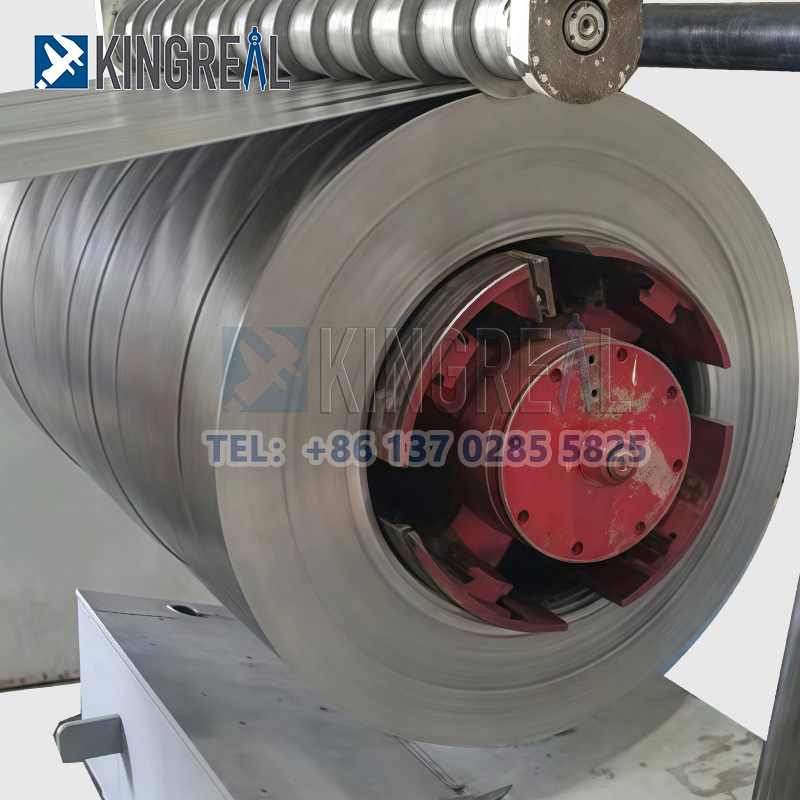

Re-coiler and separator |

1 |

Hydraulic Coil Car -- Hydraulic Decoiler -- Pinch Leveler Shear -- Front loop&Bridge -- High Speed Slitting Machine-- Rear loop Pit & Bridge -- Sheet Transmission Belt-- Recoiler

|

1. Hydraulic Decoiler Single cantilever structure bearing capacity: 12 Tons. Macimum Support: 500mm. Decoiler Method: hydraulic tension. Electric unwinding power: 7.5KW frequency conversion. Hydraulic pump: 4Kw. For materials weighing up to 12 tons, KINGREAL has created an uncoiling trolley that can finish the rewinding process. |

|

|

2. High-speed slitter component The most crucial component of the entire production line for slitting machines is the slitting parts, the caliber of which directly affects the caliber of slitting. To create the 10mm-thick slitting blade, KINGREAL uses Cr12Mov alloys. |

|

3. Tensioner and pre-separator It is made up of base, press roller, tensioner, pinch rollers, shear, and two pre-separating rollers. |

|

KINGREAL STEEL SLITTER is one of the most professional coil processing equipment manufacturers in China. Its main coil processing equipment includes slitting machines and cut-to-length lines, and also provides customized coil solutions for other industries.

KINGREAL STEEL SLITTER has engineers and technicians with extensive expertise to meet various customer needs, as well as its own processing plant to produce high quality machines.

1.Provide Installation Services

In order to help our customers to solve machine installation problems, KINGREAL will provide both online and local installation services.

2.Local After-Sale

In order to be able to effectively solve customer needs in the first time, KINGREAL has set up localized service points in many countries and regions, such as India, Russia, Turkey, the United Arab Emirates and Qatar.

Localized service points in other countries and regions are also in progress.

1. How to operate the stainless steel slitting machine safely?

2. How to do a good job of acceptance of the steel slitting machine?

3. Factors affecting the width of the coil slitting machine

4. What is the role of the sensor in the coil slitting machine?

5. How to operate the tension system of coil slitting machine?