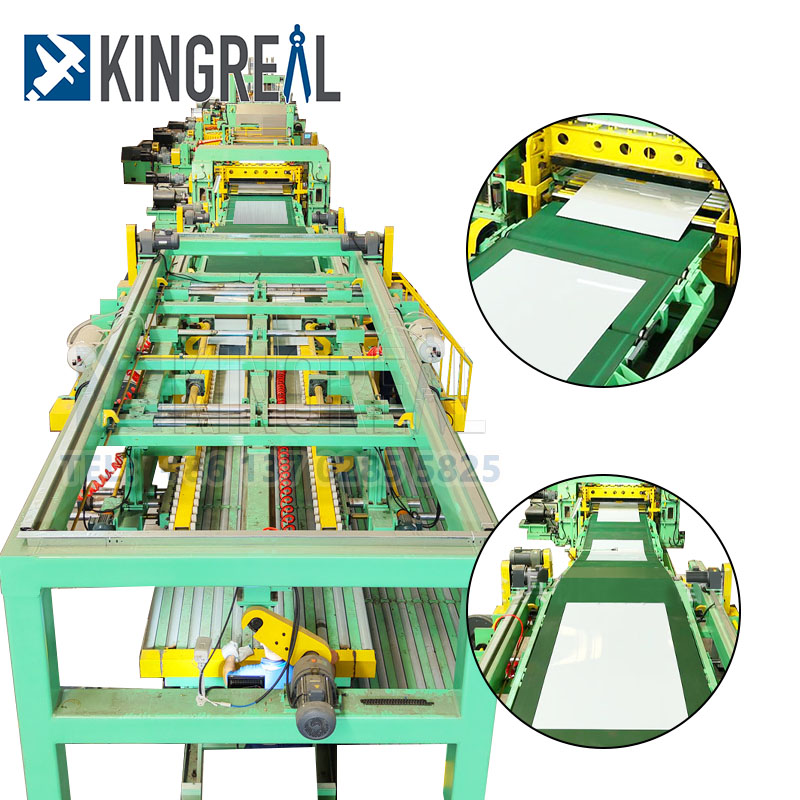

KINGREAL STEEL SLITTER has specially designed the Cut To Length Line With Trimming, aiming to provide customers with better quality metal sheets.

Video About Cut To Length Line With Trimming

Video About Cut To Length Line With Trimming

What Is Cut To Length Machine?

What Is Cut To Length Machine?

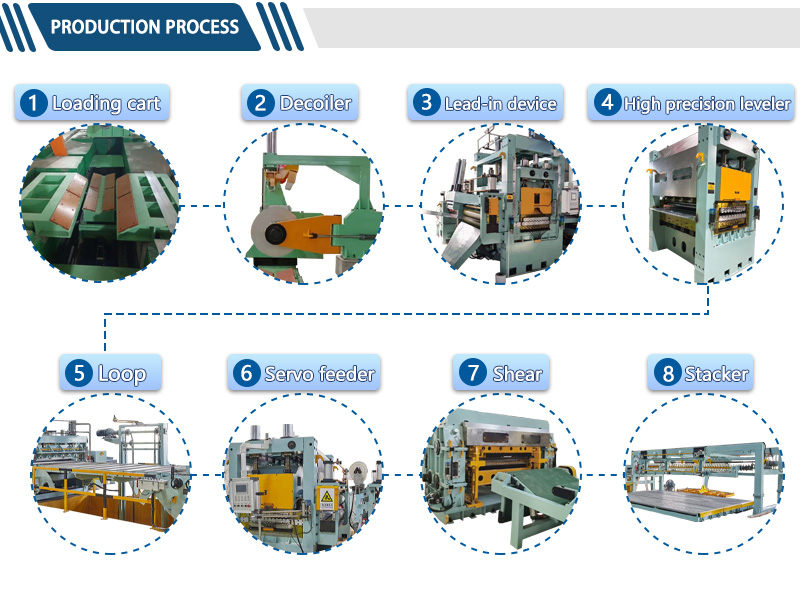

The KINGREAL STEEL SLITTER Cut To Length Machine with Trimming processes uncoiling, leveling, tension, cross-cutting and stacking to process metal coils of different sizes into products of specific dimensions.

The cut to length line with trimming is mainly used in the process of cutting, cross-cutting and dividing plates of stainless steel, aluminum plates, iron plates, hot-rolled steel and cold-rolled steel, etc.

This cut to length line with trimming is suitable for material processing in printing, packaging, automotive electronics, clothing and apparel, furniture and hardware, building materials and other industries.

Why Does Cut to Length Line Need To Be Trimmed?

Why Does Cut to Length Line Need To Be Trimmed?

Machine in the production process, especially the cut to length line such large machines, due to the thickness of the coil material varies, inevitably there will be scratches on the final product or shear when it is hairy edge, etc.

In the current era of high-speed development of major industries, consumer requirements for high-precision leveling machine has entered a new period.

Not only to improve the flatness of the panel, but also require that the surface of the panel should not have deformation such as scratches and creases caused by the leveling process. Especially for the leveling of automobile panels and decorative panels, it is necessary to maintain good surface quality.

Therefore, KINGRERAL STEEL SLITTER specially designed and added the trimming device in the cut to length line, which greatly improves the quality of the sheet after processing.

Why is there a possibility of damage to the processed plate?

Why is there a possibility of damage to the processed plate?

When leveling the plate, it will not cause obvious scratches due to the small leveling force and smooth contact between the roller surface and the plate, which reduces friction. In most cases, it will not affect the quality of the plate.

However, for the obvious scratches caused by thick plate forming.

The greater the difference in bending rate between adjacent rolls, the greater the deviation in plate movement speed between rolls, although the deviation in movement speed generated when the plate passes through the rolls results in traversing scratches caused by lateral pressure that are difficult to remove.

In addition to this, the usage time of the cut to length machine with trimming and the maintenance intervals of the main equipment such as the blades affect the quality of the final product.

Technical Parameters of Cut to Length Line with Trimming

Technical Parameters of Cut to Length Line with Trimming

|

Coil Width |

500-1300MM |

|

Coil Thickness |

0.4-3.0MM |

|

Max Weight |

10 Ton |

|

Coil Inner Diameter |

450-650MM |

|

Outside Diameter |

1800MM |

|

Line Speed |

15M/Min |

|

Length Range |

400-3000MM |

|

Length Tolerance |

±0.5/Min |

|

Total Power |

20KW |

The actual data needs to be professionally designed by KINGREAL STEEL SLITTER engineers according to different production requirements.

Final Product Display

Final Product Display

KINGREAL STEEL SLITTER Cut to Length Line Factory

KINGREAL STEEL SLITTER Cut to Length Line Factory

If you want to know more details about the production line, please feel free to contact us.