The stretch levelling cut to length lines are specially designed for straightening metal sheets and coils and can also be used in conjunction with metal cut to length machines.

Stretch levelling cut to length line is a device specifically designed to straighten metal sheets and coils (including stainless steel, steel, hot-rolled steel, aluminum, and copper). Levelling Cut To Length Line uses mechanical force to correct defects such as bends, twists, and warps, resulting in uniform, straight, and evenly distributed surfaces. A stretcher leveler machine can straighten materials in either one or two directions and features ease of operation, high efficiency, and high precision. During the production and processing of aluminum alloy sheets or coils, unevenness often occurs due to various reasons, necessitating straightening with a stretch levelling cut to length line. Stretcher leveler machine can improve the flatness and surface quality of the metal material, effectively reduces the breakage rate, and avoids quality issues caused by uneven sheet or coil material.

In general, stretch levelling cut to length lines are essential equipment for metal processing. They play a crucial role in metal processing, improving the precision and quality of metal materials, enhancing the surface quality and mechanical properties of finished products, reducing the likelihood of problems in the production and use of subsequent products made from the metal materials, and improving production efficiency and economic benefits. They have broad application prospects.

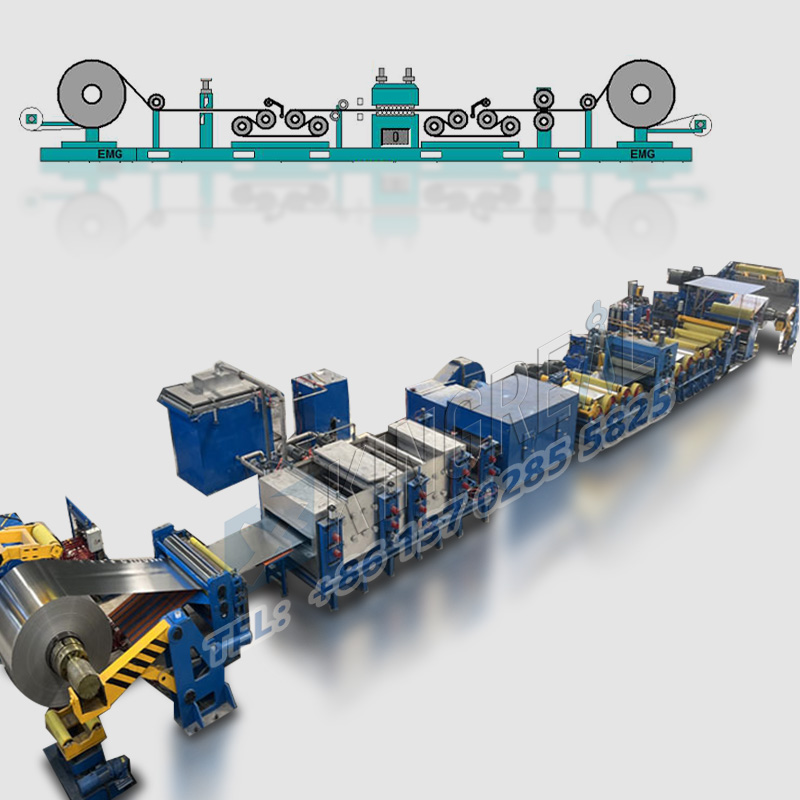

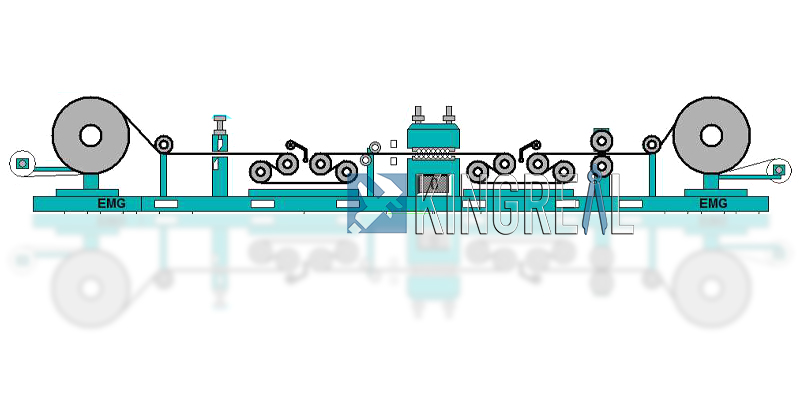

Decoiler - Pinch Device - Crop Shear - Pinch Rollers - Inlet Tension Roller Set - Straightener - Exit Tension Roller Set - Exit Deflector Rollers - Recoiler

Item

Model 1

Model 2

Model 3

Model 4

Model 5

Maximum leveling thickness (mm)

2

2

3

3

6

Minimum leveling thickness (mm)

0.4

0.4

0.7

0.7

1.5

Maximum leveling width (mm)

1000

1250

1250

1500

1600

Material load-bearing strength (MPa)

240

240

235

235

240

Working roll diameter (mm)

48

48

60

60

95

Working roll distance (mm)

50

50

65

65

100

Number of slit products (n)

21

21

19

19

13

Machine speed (m/min)

6

6

7

7

10

Main motor power (kW)

7.5

7.5

11

15

37

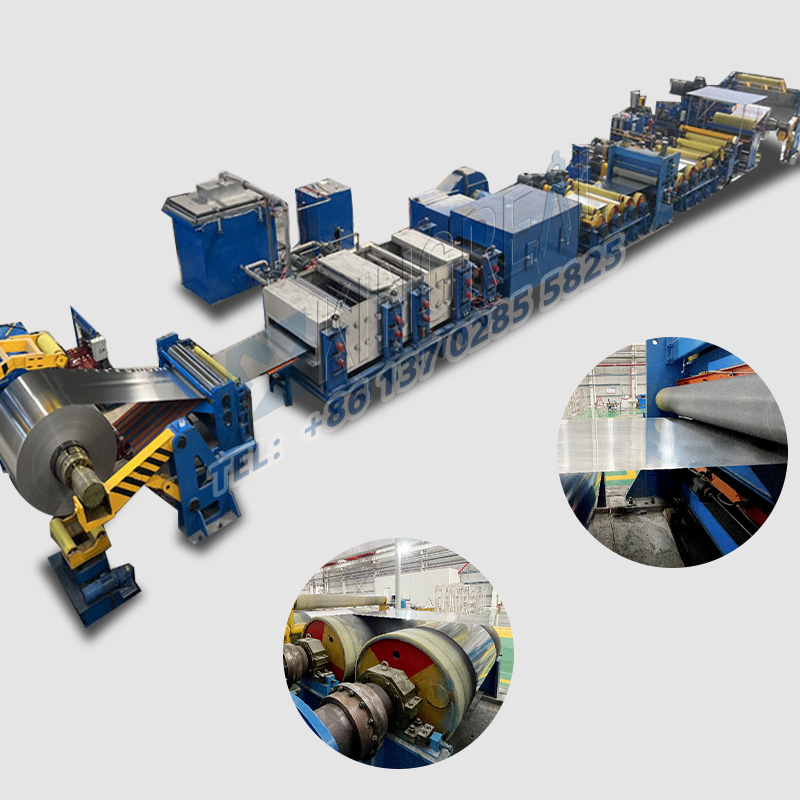

-Decoiler for stretch levelling cut to length line: Unwinds the coil for subsequent processing.

-Crop shear for stretcher leveler machine: The crop shear is used to shear the ends of metal sheets. When a sheet exhibits significant camber, it can be segmented to reduce shearing at the edges and improve yield.

The crop shear primarily consists of a tail pusher, shear body, blade changer, and oscillating roller table.

-Straightener for stretcher leveler machine: The straightener primarily consists of two sets of tension rollers, a central bending roller, and a leveling roller.

As the metal coil or sheet passes through the leveler, the tension applied by the tension rollers and the bending stress applied by the bending rollers combine.

This combined stress causes the strip to undergo a certain amount of plastic elongation, which is then leveled by the leveling rollers.

This method of straightening offers high-quality straightening and can be used to straighten a variety of metal materials, including high-strength strip.

-Inlet tension roller set & exit tension roller set for stretcher leveler machine: The tension generated between these two rollers is the tension in the straightening section. It prevents the strip from deviating, maintains a straight shape, and reduces the metal's deformation resistance and work.

-Recoiler for stretch levelling cut to length line: The straightened metal coil is coiled for easy long-distance transportation and storage.

1. Improving strip shape

The primary function of a stretcher leveler machine is to improve the strip shape of metal strip. By stretching and bending the strip, it effectively eliminates wavy defects such as edge and center waves, as well as C- and L-shaped bends. This process significantly improves the strip's straightness, resulting in greater stability and consistency during subsequent processing.

2. Improving processing performance

In addition, a stretch levelling cut to length line can improve the strip's processing performance. By stretching and bending, similar to the effect of skin-finishing, it can reduce or eliminate yield plateaus, resulting in uniform deformation during subsequent deformation.

This uniformity improves the material's processing performance, making it easier to handle and suitable for various subsequent processes.

1. Advanced control system for stretcher leveler machine

The stretch levelling cut to length line utilizes a PLC system, allowing for adjustment of multiple production parameters on the control panel, including unwinding tension, speed settings, entry and exit heights, and exit inclination. This automated control improves production efficiency and reduces human error.

2. Four-roller structure for stretcher leveler machine

The stretch levelling cut to length line utilizes an advanced four-roller structure, enabling fully hydraulic automatic hold-down adjustment and flexible adjustment of the shape bending rolls. This design ensures stability and consistency during the tension and leveling process.

3. AC variable frequency speed control for stretcher leveler machine

The main rolling mill utilizes an AC variable frequency speed control system, combined with Siemens PLC control, ensuring smooth operation and efficient production.

4. Fully hydraulic screwdown system for stretcher leveler machine

The hydraulic AFC (Automatic Screwdown Control) system is PLC-controlled and features a constant roll gap position closed-loop and a constant rolling force closed-loop. This system ensures precise control during the straightening process, improving product quality.

5. Production process automation for stretcher leveler machine

The unit features process interlocking, weld detection, and alarm functions, enabling automated management of the production process. This significantly enhances equipment safety and reliability.

6. Parameter presetting and monitoring for stretcher leveler machine

The stretch levelling cut to length line supports presetting, detection, display, alarm, and storage of process parameters for easy user query and management. This intelligent management approach makes operation simpler and more intuitive.

7. Stable structural design for stretcher leveler machine

The entire stretch levelling cut to length line is equipped with a cast iron frame panel and cast iron chassis, ensuring stable operation, reducing vibration, and extending the stretcher leveler machine’s service life.

8. Easy operation for stretch levelling cut to length line

The stretcher leveler machine is designed for ease of operation, allowing even novice operators to quickly master the machine and ensure efficient production.

KINGREAL STEEL SLITTER offers customers both stretch levelling cut to length lines and metal cut to length lines, making them an ideal combination. The stretcher leveler machine first smoothes the surface of the metal coil and reduces internal stresses, before feeding it into the metal cut to length machine for cutting to a predetermined length. KINGREAL STEEL SLITTER offers a variety of metal cut to length machines, including light gauge cut to length production line, medium gauge cut to length line, and heavy gauge cut to length line, depending on the thickness of the material being processed.

KINGREAL STEEL SLITTER also offers fly shearing cut to length machine, rotary shearing cut to length machine, and fixed shearing cut to length machine, allowing customers to choose based on production efficiency, scale, and target output. KINGREAL STEEL SLITTER engineers will provide comprehensive recommendations based on specific customer needs to ensure optimal equipment coordination and performance.

|

|

|

Stretcher Leveler Machine |

Metal Cut To Length Machine |

1. Automotive Manufacturing: Stretch levelling cut to length lines are used in the automotive industry during the body sheet metal processing process to straighten and stretch the sheet metal to meet automotive quality requirements.

2. Construction Industry: Stretcher leveler machines are used in the construction industry to straighten and stretch steel plates during steel structure fabrication to ensure the stability and strength of the steel structures.

3. Electronic Equipment Manufacturing: In this industry, stretch levelling cut to length lines are used to straighten and stretch metal sheets or films to meet the flatness and conductivity requirements of electronic components.

4. Aerospace Industry: In this industry, stretcher leveler machines are used to straighten and stretch aircraft skin panels to improve their strength and overall quality.

5. Metalworking Industry: In this industry, stretch levelling cut to length lines are used to straighten and stretch various metal sheets to meet the processing requirements of diverse workpieces.