Cut to length line plays a vital role in modern manufacturing. It is mainly used to make flat plates of the required length and stack them after uncoiling, leveling, sizing, shearing and other processes. These coil cut to length lines are suitable for a variety of metal materials, including cold-rolled and hot-rolled carbon steel, silicon steel, tinplate, stainless steel and other different metal materials. The function of the cut to length line is not limited to shearing, but also includes improving the flatness and precision of the material to ensure that each piece of metal plate meets strict quality standards.

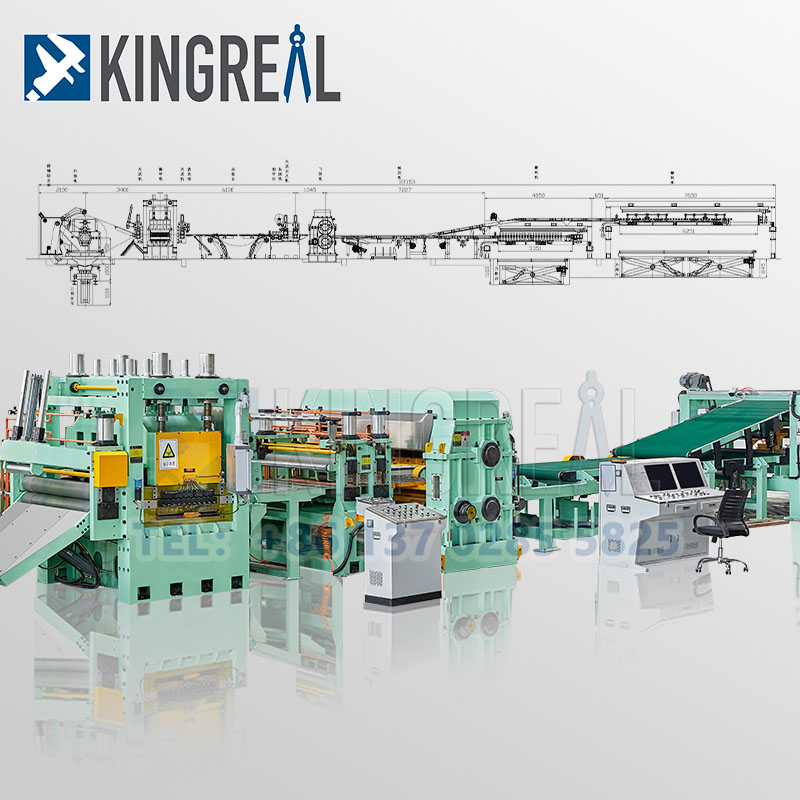

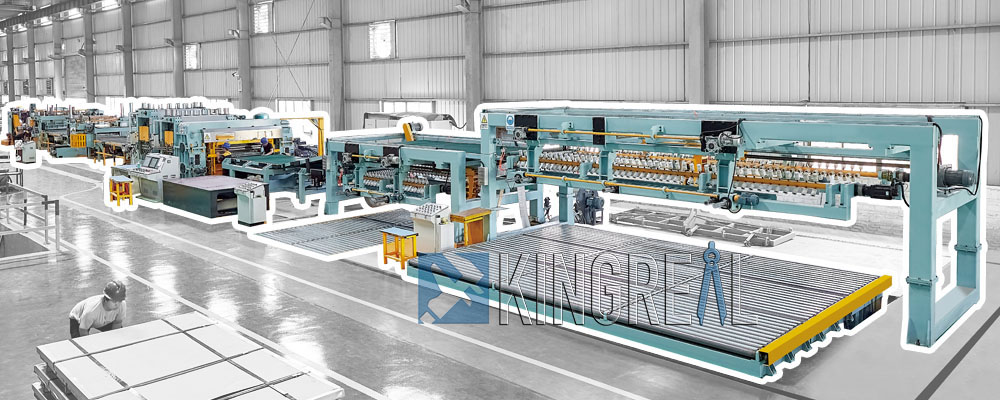

Usually the coil cut-to-length line comprises several precision components including shearing machines, stacking devices, loading trolleys, decoilers, leveling machines, feeding mechanisms, conveying systems, and decoilers. The cut to length line is easy to operate and dependable because of its great degree of automation, therefore lowering labor expenses much and increasing production efficiency. Furthermore, the coil cut to length line is often used in the metal processing industry because of its benefits of precise shearing accuracy, great plate flatness, and flawless stacking.

With the progress of society and the expansion of industrial scale, more and more companies have begun to pay attention to the technical upgrading and transformation of cut to length lines. The market demand for efficient and precise coil cut to length lines is increasing, which makes the technological innovation of cut to length lines an important trend in the development of the industry.

At present, cut to length line manufacturers on the market are able to provide diversified solutions according to the different production needs of customers. Taking KINGREAL STEEL SLITTER as an example, we have launched light gauge cut to length lines, medium gauge cut to length lines and heavy gauge cut to length lines to meet customers' needs for different coil thicknesses. Light gauge cut to length lines can handle coils with a thickness of 0.2-3mm, medium gauge cut to length lines are suitable for coils with a thickness of 0.3-6mm, and heavy gauge cut to length lines can handle coils with a thickness of 6-20mm. Such classification enables coil cut to length lines to better meet customers' production requirements while reducing resource waste.

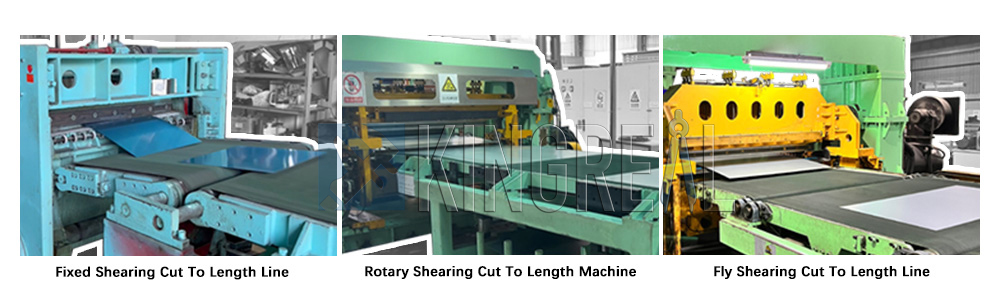

In addition, KINGREAL STEEL SLITTER has also designed various types of cut to length lines such as fly shearing cut to length lines, rotary shearing cut to length lines and fixed shearing cut to length lines according to different shearing methods. These coil cut to length lines perform well in meeting customers' different needs for shearing methods and shearing speeds. Usually, the speed of fixed shearing cut to length line is 50m/min, while the speed of fly shearing cut to length line and rotary shearing cut to length line can reach 80m/min. Showing their value in metal sheet processing, these effective coil cut to length lines are often utilized in sectors including cars, domestic appliances, food, packaging, and ornamental construction materials.

With the continuous advancement of science and technology, the future coil cut to length line will move towards a more efficient, intelligent and sustainable development. KINGREAL STEEL SLITTER goal is to develop a fully automated, energy-efficient cut to length line manufacturing solution by improving production efficiency and liberating manpower. At the same time, customized design is carried out in combination with the actual needs of customers, so that the coil cut to length line can show the best performance in different usage scenarios.

Among them, the application of intelligent technology will be an important trend in the development of cut to length lines in the future. By introducing advanced technologies such as the Internet of Things, big data and artificial intelligence, the coil cut to length line can monitor the production status in real time, analyze data and make intelligent decisions. This can not only improve production efficiency, but also provide timely warnings when failures occur, reduce downtime, and thus reduce production costs.

In addition, with the enhancement of environmental awareness, the sustainable development of cut to length lines will also become an important research direction. In the future, coil cut to length lines will pay more attention to environmental protection in terms of material use, energy consumption control and waste treatment. For example, the use of energy-saving motors and advanced control systems can effectively reduce energy consumption; optimize the shearing process and reduce the generation of metal waste, thereby achieving more efficient use of resources.

In essence, as a critical tool in the metal processing sector, coil cut to length lines are evolving toward sustainability, intelligence, and efficiency. Given the ongoing technical developments and shifting market demand, the future of cut-to-length lines offers many options. Companies should actively investigate and use new technologies to satisfy the expanding market demand and maximize their financial advantages, thereby keeping pace with the times.

The importance of cut to length lines in modern manufacturing is self-evident. From improving production efficiency to ensuring product quality, the advanced technology and innovative design of coil cut to length lines are driving the development of the entire industry. In the future, as the concepts of intelligence and sustainable development are deeply rooted in the hearts of the people, cut to length lines will continue to play their irreplaceable role in the field of metal processing. When selecting and using coil cut to length lines, enterprises should fully consider their own production needs and future development trends to achieve more efficient production and better quality products.