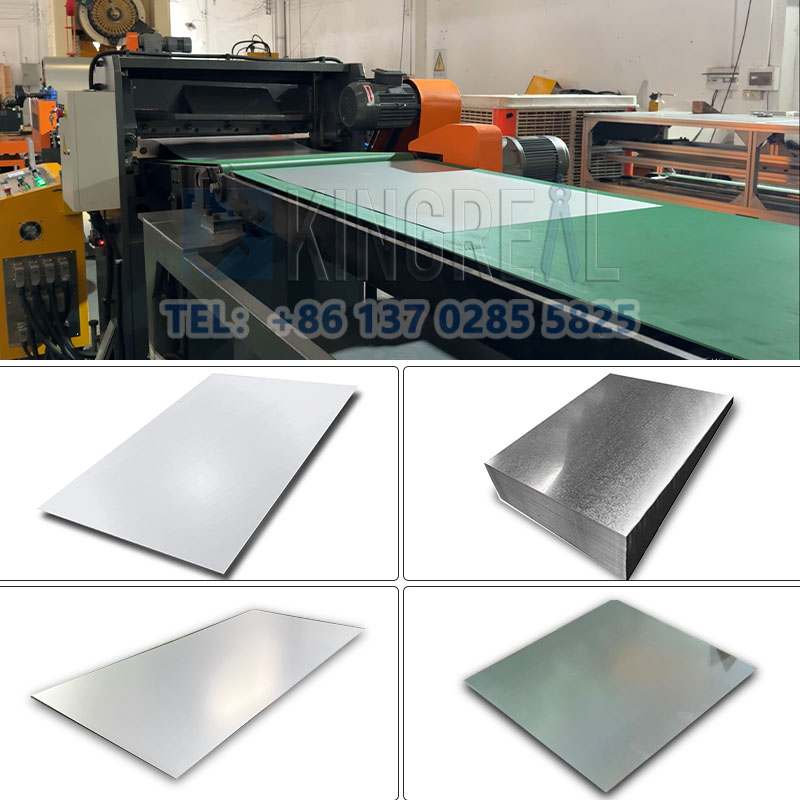

Compact cut to length line is one of the special metal cut to length machines that KINGREAL STEEL SLITTER can provide. KINGREAL STEEL SLITTER can provide customers with a wide variety of drivers, controllers and applications to ensure that customers get high-quality compact cut to length machines that meet the reliability and accuracy expected of the finished product.

KINGREAL STEEL SLITTER can provide different compact cut to length line manufacturing solutions according to the actual production needs of customers. In this article, KINGREAL STEEL SLITTER will introduce the compact cut to length machines that KINGREAL STEEL SLITTER can provide to customers in detail. Hope you can get help.

In addition to the compact cut to length machine, KINGREAL STEEL SLITTER can also provide other types of metal cut to length machines, such as:

Medium Gauge Cut to Length Machine,

Heavy Gauge Cut to Length Machine,

Fly Shearing Cut to Length Machine,

Swing Shearing Cut to Length Machine,

Rotary Shearing Cut to Length Machine,

Fixed Shearing Cut to Length Machine,

...

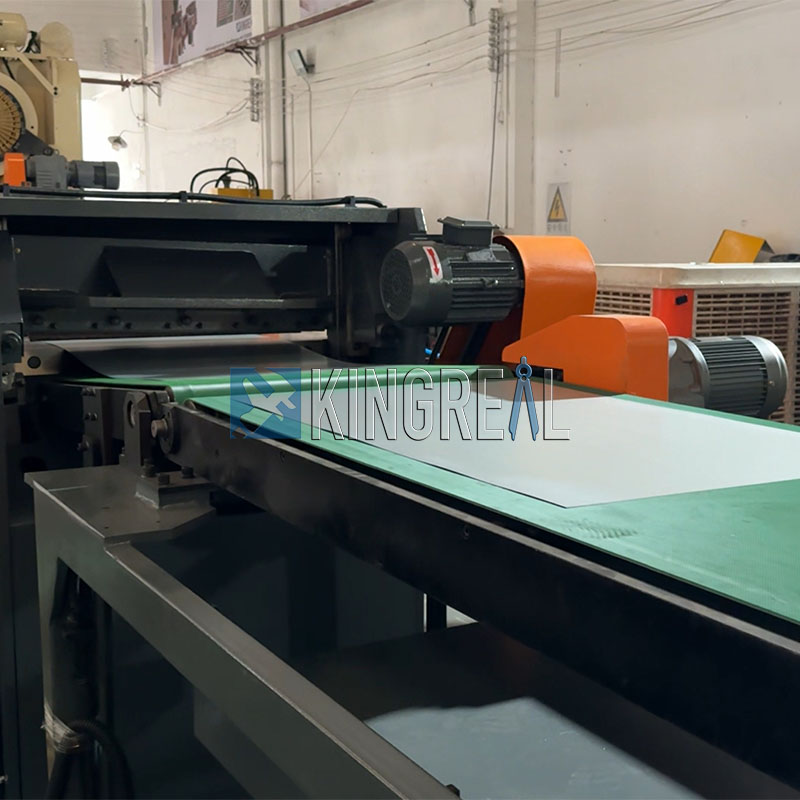

Decoiler , Leveling machine, Shearing machine, Stacking machine

The following are optional configurations that KINGREAL STEEL SLITTER can provide to customers according to their actual situation:

① Laminating device for compact cut to length line

For some customers, the surface quality of metal sheets is very important, especially for high-end products, any scratches may affect their appearance and performance. For this reason, KINGREAL STEEL SLITTER provides a laminating device that can cover the surface of the metal coil with a protective film before it is fed into the compact cut to length machine. This film can not only effectively prevent scratches, but also resist oxidation and corrosion, extending the service life of the metal sheet. By using a compact cut to length line equipped with a laminating device, customers can ensure that the metal sheets are always in the best condition during subsequent processing and transportation.

② Double leveler for compact cut to length machine

In some industries, customers have extremely high requirements for the flatness of metal sheets, especially in situations where precision processing is required. To meet this demand, KINGREAL STEEL SLITTER can equip the compact cut to length machine with a double leveler. By passing the metal coil through two leveling processes, the flatness will be significantly improved. This design of equipping the compact cut to length line with a double leveler can effectively eliminate the bending and waves of the material, ensuring that the cut metal sheets are flat and uniform, thereby improving the accuracy and quality of subsequent processing.

③ Double stacking table for compact cut to length machine

In order to improve the production efficiency of the entire process and reduce labor costs, KINGREAL STEEL SLITTER has equipped the compact cut to length machine with a double stacking table. This design allows metal sheets to be stacked quickly, saving time and energy for manual handling. The compact cut to length machine equipped with a double stacking table not only improves work efficiency, but also ensures the stability and safety of stacking. Through the automated stacking process, customers can focus more on other important production links and further improve overall production efficiency.

① Processing of multiple materials

KINGREAL STEEL SLITTER has strong adaptability and can process different types of metal materials, including stainless steel, steel, aluminum, iron, copper and PPGI. This versatility enables our compact cut to length machine to meet the needs of various industries and help customers achieve efficient processing in different production environments.

② Small footprint

A major advantage of the compact cut to length line is its small footprint. This compact cut to length machine was designed with full consideration of the space limitations of the factory. Although it is small in size, it has all the configurations that a standard cut to length line should have to ensure that it does not affect production efficiency. This undoubtedly provides great convenience for customers with limited plant space.

③ High degree of automation

The compact cut to length machine is composed of multiple precision components such as decoiler, leveling machine, shearing machine, stacking table, etc., which minimizes the need for manpower. The automated operation of the compact cut to length line not only improves production efficiency, but also ensures the stability of product quality. Through this efficient production process, customers can significantly reduce labor costs while improving overall production capacity.