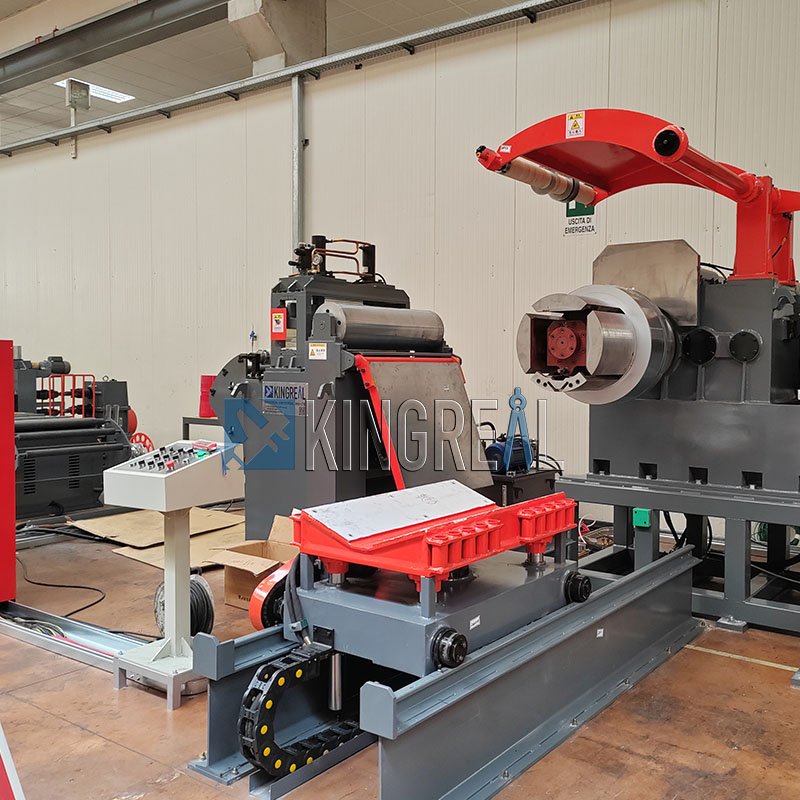

Last month, KINGREAL STEEL SLITTER successfully delivered a brand new steel coil slitting line to the Italian customer's factory and sent a professional team of engineers to the customer's factory to install the steel coil slitting machine and conduct operation training. Next, KINGREAL STEEL SLITTER will review the entire process in detail, including steel coil slitting line inspection, installation, commissioning, testing and operation training.

After the steel coil slitting machine arrived at the customer's factory, KINGREAL STEEL SLITTER engineers unpacked the package with the Italian customer and carefully inspected the various components of the steel coil slitting line. This step is crucial because the steel coil slitting machine may suffer various damages during long-distance transportation.

The engineers first checked the surface condition of the steel coil slitting line to ensure that there were no obvious scratches or dents. Then, they checked the integrity of each component one by one, including the tool, hydraulic system, control panel, etc. In addition, KINGREAL STEEL SLITTER engineers also checked the equipment's accessories list to ensure that all necessary parts have been delivered with the steel coil slitting machine.

After completing the inspection, KINGREAL STEEL SLITTER engineers began to install the steel coil slitting machine. KINGREAL STEEL SLITTER engineers first evaluated the layout of the Italian customer's factory to determine the best installation location for the steel coil slitting line. Considering the actual working environment, the engineers decided to use a forklift to move the various components to the predetermined location.

After determining the approximate location, the engineers began to assemble the steel coil slitting machine step by step. This process requires meticulousness, because the installation of each component is directly related to the normal operation of the steel coil slitting line. KINGREAL STEEL SLITTER engineers strictly follow the procedures specified in the KINGREAL STEEL SLITTER installation manual to ensure that each component is tightly connected and meets the design requirements.

|

|

|

After the steel coil slitting line was installed, KINGREAL STEEL SLITTER engineers entered the trialing stage. KINGREAL STEEL SLITTER engineers performed the following important steps:

3.1 Knife installation

In the installation of the knife, KINGREAL STEEL SLITTER engineers strictly followed the established order and correctly installed the slitting circular knife, spacer ring and composite pusher ring into the knife shaft in turn. During this process, KINGREAL STEEL SLITTER engineers paid special attention to checking the position of the knife and the accuracy of the knife gap to ensure that the cutting quality meets the expected standards.

3.2 Installing the hydraulic nut

After the installation of various tools on the knife shaft, KINGREAL STEEL SLITTER engineers carefully installed the hydraulic nut. The hydraulic nut is an important component to ensure that various tools on the knife shaft are tightly combined. Only after proper installation can a stable and rigid shearing system be formed.

3.3 Trial cutting stage

The trial cutting stage is an extremely important part of the trailing process. KINGREAL STEEL SLITTER engineers selected metal plates and strips for trial cutting, comprehensively considering the thickness, material and tensile strength of the plates and strips, and accurately selected the overlap of the upper and lower knives based on this. In the initial trial cutting, KINGREAL STEEL SLITTER engineers tested by manually pulling the strip to observe the cutting effect.

If there is no abnormality during the trial cutting, KINGREAL STEEL SLITTER engineers consider that the increase in speed during formal shearing may cause deformation of the knife shaft. Therefore, they may appropriately increase the overlap of the knives slightly to ensure that the strip will not be unable to be cut under high-speed shearing.

|

|

|

After the above trailing and testing, KINGREAL STEEL SLITTER engineers officially started the steel coil slitting line for the final test. They were concerned about whether the steel coil slitting machine could run smoothly, especially when processing different metal materials (such as galvanized sheet, stainless steel, copper, aluminum, etc.). In addition, KINGREAL STEEL SLITTER engineers also tested whether the steel coil slitting line could cut narrow strips of different widths to ensure that the versatility of the equipment could meet customer needs.

Throughout the testing process, KINGREAL STEEL SLITTER engineers carefully observed every link to ensure that every function of the steel coil slitting machine was working properly.

|

|

|

After completing the preliminary tests, KINGREAL STEEL SLITTER engineers conducted further inspections on the finished products. They conducted a series of quality checks on the narrow strips produced under the same parameters to ensure their consistency, burr-free and error within the range of ±1.0mm. This step is an important part of ensuring product quality and is crucial for the subsequent production activities of Italian customers.

KINGREAL STEEL SLITTER engineers checked each narrow strip one by one by using high-precision measuring tools.

|

|

|

In order to ensure that Italian customers can operate the steel coil slitting line proficiently, KINGREAL STEEL SLITTER engineers also conducted detailed operation training. The training was divided into two parts: First, KINGREAL STEEL SLITTER engineers operated the steel coil slitting machine themselves, demonstrating basic operations such as how to adjust the production speed and adjust the width of the narrow strips.

During the demonstration, KINGREAL STEEL SLITTER engineers emphasized the precautions in operation to ensure that the Italian customers' workers could fully understand how to use the steel coil slitting machine. Afterwards, KINGREAL STEEL SLITTER engineers invited the workers to try one by one and observe their operation process.

During this process, KINGREAL STEEL SLITTER engineers found some problems that Italian workers had in operation and gave timely guidance and corrections. Through repeated practice and guidance, it is ensured that each worker can operate the steel coil slitting line independently and master the various functions of the equipment. At the end of the training, KINGREAL STEEL SLITTER engineers evaluated the operation level of each worker to ensure that they can effectively apply the knowledge they have learned in actual production.