Before mass production of automotive panels, appliance housings or furniture frames, metal coils must first be cut into specific widths by cold rolled slitting machines, which is a crucial processing stage.

Only by cutting narrow strips through cold rolled slitting lines can the subsequent manufacturing needs of various products, from small electronic parts to tank trailer sidewalls, be met.

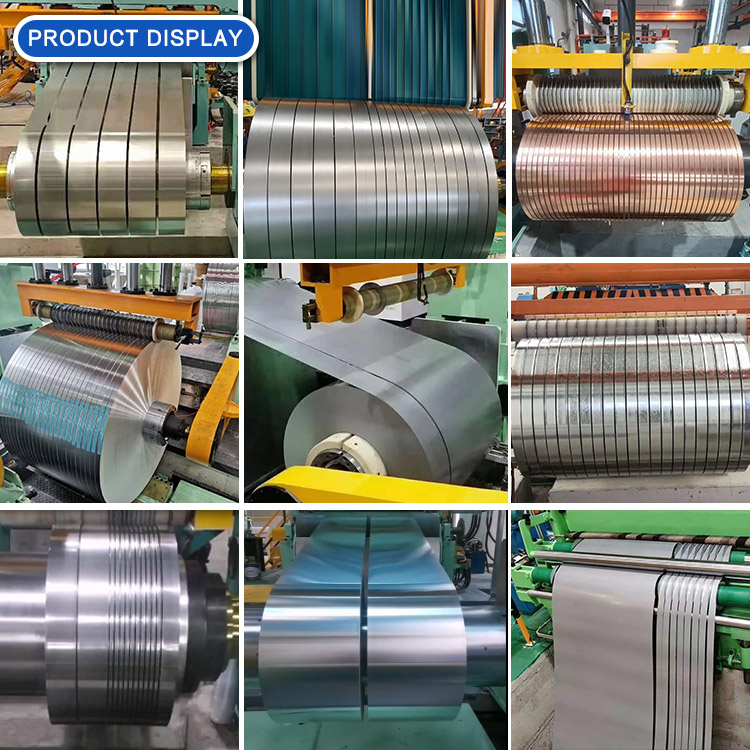

But how do these cold rolled slitting machines perfectly cut heavy, large coils of metal into multiple narrow metal strips with strict tolerances? Below KINGREAL STEEL SLITTER will analyze the cold rolled slitting line and its slitting process in detail for you to reveal the answer!

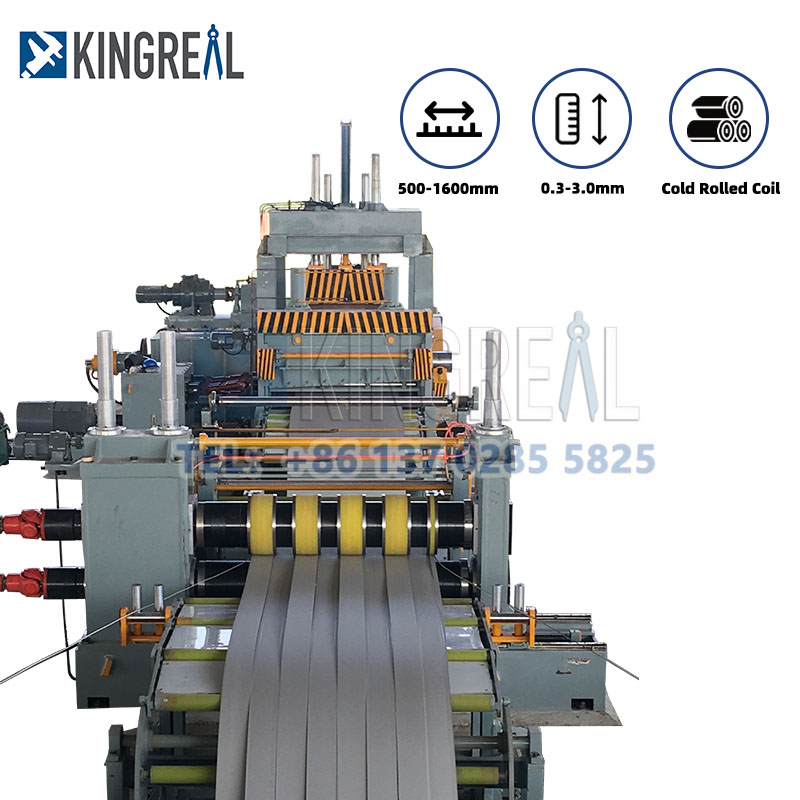

A cold rolled slitting line is generally composed of four main parts: decoiler, precision disc knife seat, (belt, plate tension generating station), winder, and of course auxiliary devices such as conveyor, clamping machine, plate head shearing machine, buffer, guide, winding waste edge, winding shearing machine, and discharge. The cold rolled slitting machine has high compatibility. From the light gauge slitting machine for hot-rolled coils to the precision heavy gauge slitting machine for cold-rolled ultra-thin materials, the thickness of the strip steel can range from 0.1-6.0mm and the width can range from 200-2100mm. In addition, the weight and thickness of the metal coils and the customer's requirements for the product surface are different. KINGREAL STEEL SLITTER can provide customers with cold rolled slitting lines of different specifications and equipment configurations.

KINGREAL STEEL SLTTER can provide personalized cold rolled slitting line manufacturing solutions based on the customer's actual production needs and combined with drawings. Since the actual needs of each customer are slightly different, each cold rolled slitting machine sold by KINGREAL STEEL SLITTER is unique, and the parameters and configurations will vary according to the specific needs of the customer. The following are the special cold rolled slitting lines that KINGREAL STEEL SLITTER can provide:

(1) Cold rolled slitting machines designed according to the thickness of metal coils. According to the different requirements of different industries for the thickness of metal coils, KINGREAL STEEL SLITTER has designed three types of cold rolled slitting lines: light gauge slitting machines, medium gauge slitting machines and heavy gauge slitting machines.

Light gauge slitting machines: can process metal coils of 0.2-3mm

Medium gauge slitting machines: can process metal coils of 3-6mm

Heavy gauge slitting machines: can process metal coils of 6-16mm

![]()

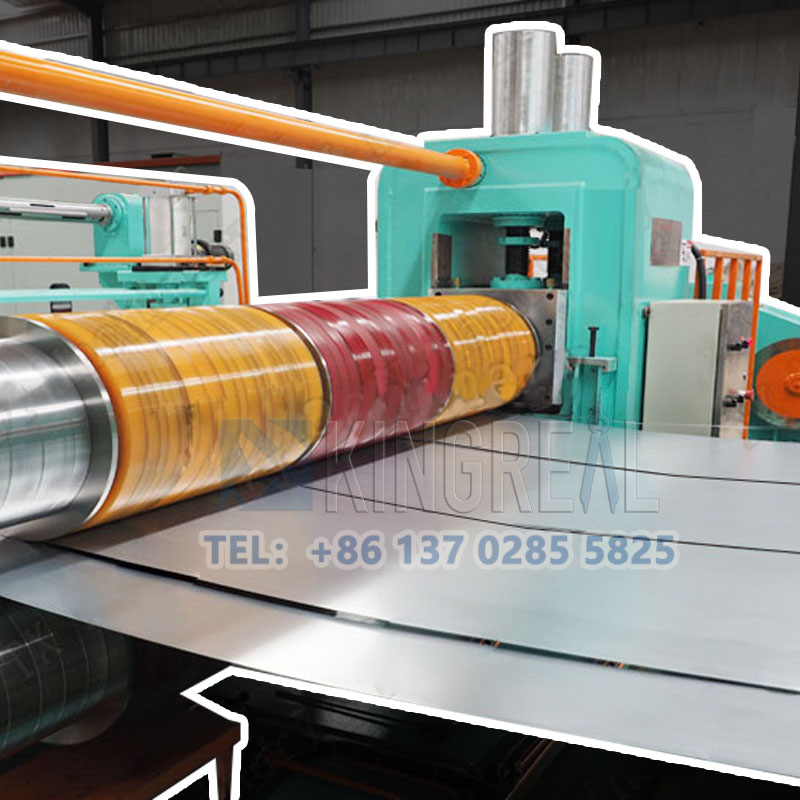

(2)Cold rolled slitting machines designed according to different metal materials. Since each customer needs to process different metal materials, KINGREAL STEEL SLITTER has designed cold rolled slitting lines, hot rolled slitting machines, stainless steel slitting machines, copper slitting machines, PPGI slitting machines, etc., and these metal coil slitting machines are usually compatible with a variety of metal materials to meet the diverse processing needs of customers.

![]()

(3) Cold rolled slitting lines designed according to the personalized production needs of customers. KINGREAL STEEL SLITTER customizes dual slitter head slitting machines and belt tension coil slitting machines according to the actual production needs of customers.

This dual slitter head slitting machine uses two sets of movable cutter heads, which can move laterally along the track (online/offline) and can also be moved longitudinally by a trolley to achieve interchangeability. The online cutter head is equipped with a hydraulic locking mechanism. The two sets of cutter heads share power, using an AC motor to drive the upper and lower cutter shafts through a gear box and a universal joint.

The tension part of this belt tension coil slitting machine uses belt tension to ensure that the board surface is intact and without marks. The sensitive control system senses and will not cause material pulling or tearing. Combined with the design basis of the standard cold rolled slitting machine, it ensures the stability and accuracy of the high-speed operation of the entire cold rolled slitting line for customers.

Coil loading: The parent coil is installed on the decoiler and is ready for processing.

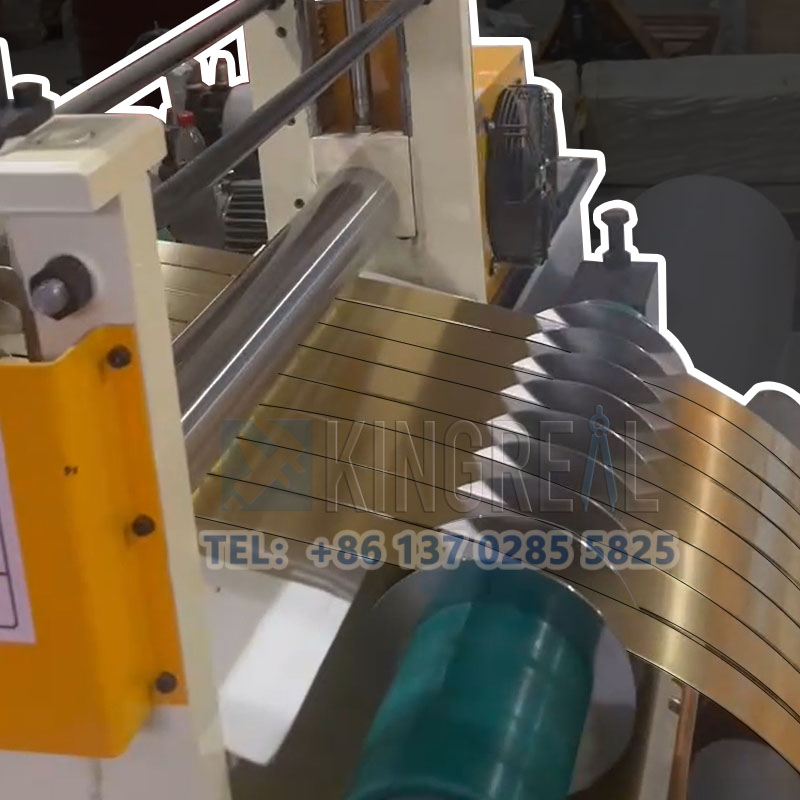

Setup and calibration: The knives and shims are precisely arranged on the blade shaft according to the required slitting width. Accurate settings ensure minimal waste and consistent processing results.

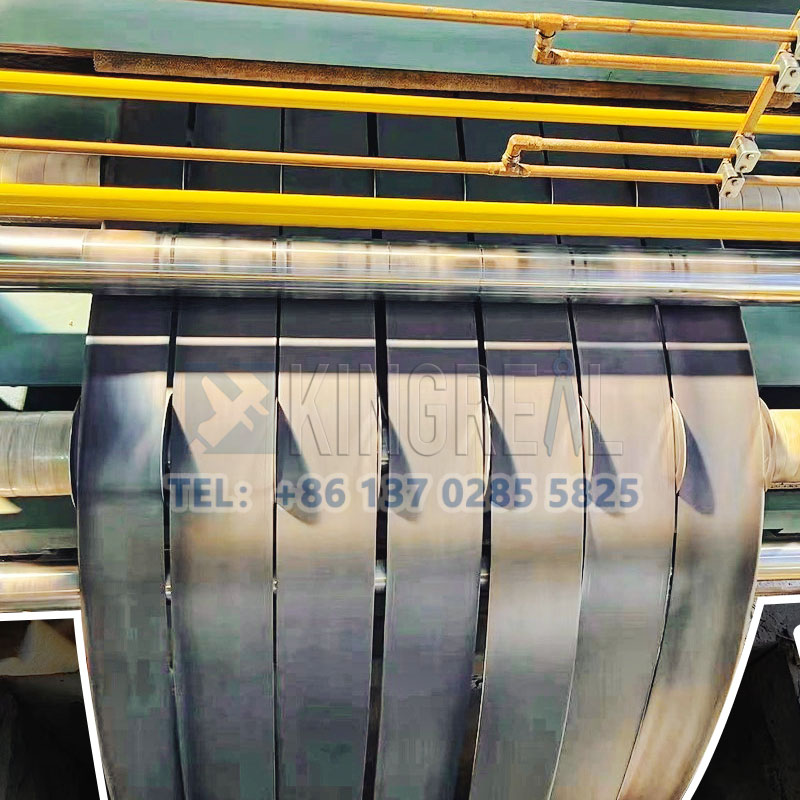

Slitting: The coil is fed through the slitter and accurately cut into narrower strips at high speed. The operator monitors calibration and performance throughout the process.

Rewinding: The slit strip is rewound onto a separate recoiler. Appropriate tension is applied to form a uniform, tightly wound coil.

Inspection and packaging: Each slit coil is strictly inspected for dimensional accuracy and edge quality, and then safely packaged to prevent damage during transportation.

|

①High-speed cold rolled slitting machine, with a maximum production speed of up to 230m/min ②Precise cold rolled slitting line. The cold rolled slitting machine provided by KINGREAL STEEL SLITTER can guarantee the quality and accuracy of slitting, with an error within ±0.1mm. ③A large number of slitting narrow strips can be produced by cold rolled slitting line. The cold rolled slitting machine provided by KINGREAL STEEL SLITTER can slit up to 40 narrow strips at a time. ④Cold rolled slitting line with high safety performance. KINGREAL STEEL SLITTER can provide customers with cold rolled slitting machines with protective shields. The cold rolled slitting line is covered by a protective shield. When the cold rolled slitting machine is running, workers are no longer injured by accidentally touching machine parts, reducing safety hazards. |

|

Automotive

Precision slitting stainless steel coils is essential for producing parts such as structural brackets, fuel system components and exhaust elements. Tight tolerances and clean edges help improve part reliability and meet stringent safety and performance requirements. Automotive manufacturers rely on high-quality slitting coils to reduce waste, streamline production processes and ensure consistent product quality.

Aerospace

In the aerospace manufacturing industry, stringent standards require slitting coils with uniform widths and flawless edges. Applications such as turbine blades, heat ex-changers and fuselage components rely on burr-free edges and consistent flatness. Manufacturers in this industry typically choose partners who can provide superior control, traceability and quality assurance.

Energy

Fuel cell and electrolyte manufacturers require dimensionally accurate slitting coils with smooth edges to ensure optimal sealing, welding and stacking. In these power generation applications, burrs or edge defects can destroy system integrity or shorten product life. That’s why edge quality and consistency are critical in this field, and why working with a skilled coil slitting supplier is key to long-term performance and efficiency.

The above is the relevant knowledge about the cold rolled slitting machine. If you are interested in the cold rolled slitting line and hope to obtain more parameters or video materials, please feel free to consult KINGREAL STEEL SLITTER!