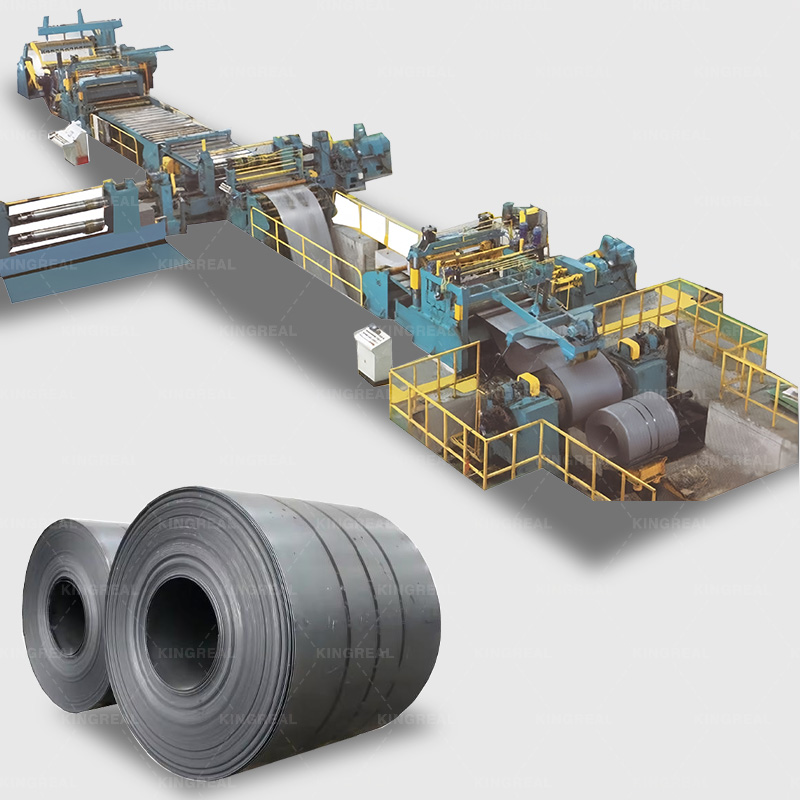

The heavy duty slitting line is specifically designed for narrow-width slitting of thicker and heavier steel plates (6-16mm). The process involves cutting steel coils into several narrow coils.

|

In the modern metal processing industry, heavy duty slitting lines are capable of efficiently cutting entire coils of steel into several narrower coils, primarily using a set of rotating slitting knives. Designed specifically for processing thicker, heavier metal coils, their cutting thickness range typically spans from 6 mm to 16 mm, depending on the type of material being processed. KINGREAL STEEL SLITTER heavy duty slitting machines can handle not only hot-rolled steel, hot-rolled and oiled steel, hot-rolled steel, and cold-rolled steel, but also various coated steels such as hot-dip galvanized steel, electro-galvanized steel, galvanized annealed steel, and aluminized zinc steel. This heavy duty slitting line is widely used in metal processing, construction, and machinery manufacturing industries, providing customers with high-quality narrow strip products. |

|

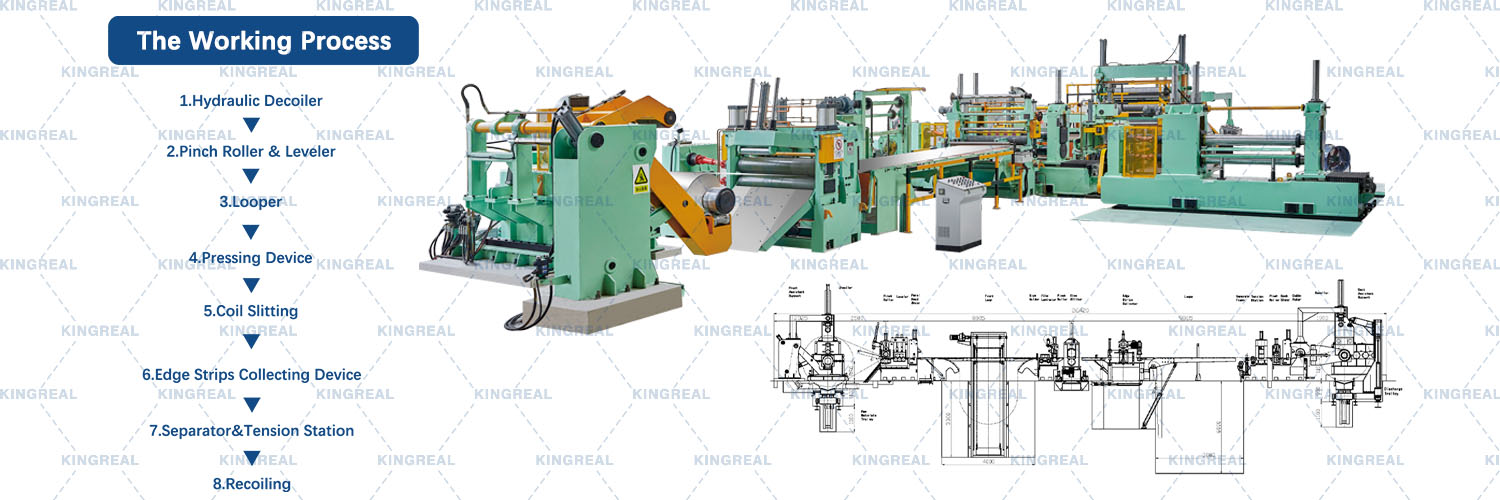

Loading → Decoiling → Snubber Roller, Pinch Roll and Leveler → Shear → Conveyor → Side Guide → Slitting Machine → Scrap Recoiler → Loop Bridge → Pre-separator and Damping → Separating and Pressing → Recoiler → Unload Cart

|

Parameter |

Specification |

|

Material Thickness |

6mm – 16mm (thicker materials customizable) |

|

Material Type |

Carbon steel, stainless steel, aluminum, high-strength low-alloy steel... |

|

Coil Width |

500mm – 2000mm |

|

Coil Weight |

Up to 40 tons (higher load capacity available) |

|

Slitting Speed |

0 – 120 meters/minute |

|

Number of Slits |

Up to 30 or more (depending on material and width) |

|

Blade Material |

High-strength alloy steel or tungsten carbide |

|

Rewinding Outer Diameter |

Up to 1600mm |

|

Tension System |

Hydraulic or pneumatic |

|

Production Line Configuration |

Fully automatic, with manual control options |

|

Control System |

PLC-based, with HMI touchscreen interface |

|

Power Supply |

380V/50Hz (or according to regional standards) |

|

Hydraulic Pressure |

15 – 25 MPa |

|

Uncoiler Load Capacity |

Up to 40 tons |

|

Recoiler Load Capacity |

Matches uncoiler specifications |

|

Slitting Blade Adjustment |

Automatic or manual, with quick change function |

|

Scrap Handling |

Includes scrap shredder |

|

Flatness Control |

Integrated leveling device for tension control |

|

Lubrication System |

Automatic centralized lubrication |

|

Safety Features |

Emergency stop, overload protection, safety guards |

|

o High-rigidity frame. The heavy duty slitting machine adopts a cast iron or welded reinforced structure to ensure its stability and durability under high-load working conditions. o High-power motor. The powerful motor drive ensures stable shearing force and improves production efficiency. o Wear-resistant carbide blades. The blades are made of high-strength materials, reducing the frequency of tool changes and lowering operating costs. |

|

1)Intelligent control system

KINGREAL STEEL SLITTER heavy duty slitting line is equipped with a self-developed intelligent CNC system. This system supports one-key storage of multiple parameter sets and real-time monitoring of key data such as tension and speed. Combined with high-precision servo drives, the slitting accuracy is ensured to be within ±0.01mm, significantly reducing material loss.

2)Modular design

This equipment adopts an original modular structure design. Core components such as the knife shaft and winding/unwinding mechanisms can be quickly replaced, compatible with the slitting needs of materials such as steel, aluminum, galvanized steel, and titanium. In addition, customers can flexibly select intelligent modules such as automatic deviation correction and online inspection according to production needs, greatly reducing heavy duty slitting machine upgrade costs.

3)Long-life design

The key components of the heavy duty slitting line use imported alloy steel and undergo vacuum heat treatment, thus improving wear resistance. The lubrication system supports remote pre-warning, and the service life of the knife holder is significantly improved.

4)Customized Service

KINGREAL STEEL SLITTER heavy duty slitting machines offer a variety of standard models with widths ranging from 600mm to 2200mm, and support non-standard customization to meet the needs of different scale production lines. In addition, the KINGREAL STEEL SLITTER team provides full-process services including "material testing, solution design, and installation training" to ensure seamless integration of the equipment with the production line.

|

|

Heavy duty slitting machines have wide applications in the metal processing field. For example, in the steel industry, they can cut wide and thick steel plates into multiple narrow plates to meet the needs of different specifications and uses; in the construction industry, they are suitable for cutting building materials such as exterior wall panels and roof panels; in the machinery manufacturing field, they can be used to cut plates required for various mechanical parts. These applications demonstrate the important role of heavy duty slitting lines in promoting industrial development.

KINGREAL STEEL SLITTER welcomes customers from all over the world to visit the KINGREAL STEEL SLITTER factory. At the factory, customers can observe the speed and efficiency of the heavy duty slitting line operation with the assistance of engineers. To date, KINGREAL STEEL SLITTER has guided customers from Poland, Kuwait, the United States, India, the UAE, and many other places to visit the KINGREAL STEEL SLITTER factory. As an excellent heavy duty slitting machine supplier, KINGREAL STEEL SLITTER can bring high-quality narrow strips to customers in various fields and projects.

KINGREAL STEEL SLITTER sincerely invites customers from all over the world to visit the KINGREAL STEEL SLITTER factory. At the factory, customers can intuitively observe the speed and efficiency of the heavy duty slitting line operation with the help of professional engineers. To date, KINGREAL STEEL SLITTER has served customers from Poland, Kuwait, the United States, India, the UAE, and other countries, demonstrating KINGREAL STEEL SLITTER strength as an excellent heavy duty slitting machine supplier capable of providing high-quality narrow strip solutions for customers in various industries.

Note: If you have any questions, please feel free to contact KINGREAL STEEL SLITTER. The KINGREAL STEEL SLITTER team will respond to you within 12 hours and provide a detailed price list and quotation!