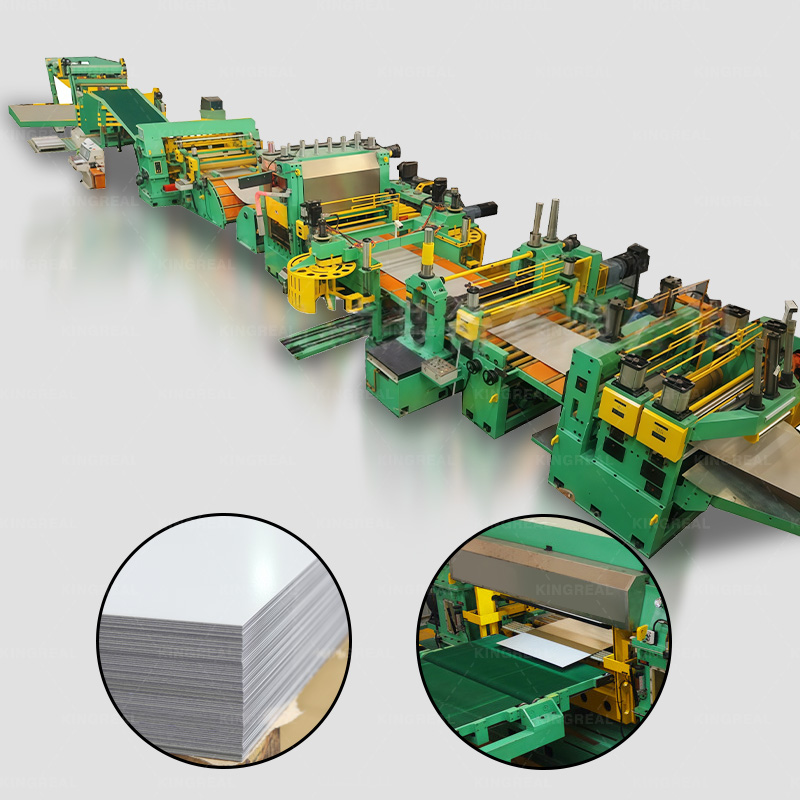

The KINGREAL STEEL SLITTER fully automatic cut to length line performs uncoiling, straightening, measuring, transverse shearing, and stacking processes on various coil materials (including cold-rolled or hot-rolled steel, tinplate, stainless steel, color-coated plates, galvanized plates, aluminum, and other metal materials).

The fully automatic cut to length machine is specifically designed for uncoiling, straightening, length setting, transverse cutting, and stacking of materials. KINGREAL STEEL SLITTER automatic cut to length lines, with their superior design and reliable performance, ensure precise feeding and high-quality cutting. Whether in high-intensity production environments or situations demanding high precision, KINGREAL STEEL SLITTER fully automatic cut to length machines provide excellent solutions.

▷Cut to Length Line | KINGREAL STEEL SLITTER 2026 Fully Automatic Cut to Length Machine◁ can be configured with either a PLC system or manual control according to customer needs. Equipped with a PLC-controlled single-axis feeder, it displays important information such as length, cutting times, and speed. The production line automatically stops after reaching the set number of cuts, improving automation and reducing manual intervention. KINGREAL STEEL SLITTER automatic cut to length line speed is adjustable, allowing users to flexibly adjust according to their needs for efficient production. In addition, equipped with high-precision measuring devices, the entire automatic cut to length machine operates automatically, making operation simple and resulting in flatter finished sheets that meet high-quality standards.

For the best automatic cut to length line manufacturing solutions, please feel free to contact KINGREAL STEEL SLITTER! With over 20 years of experience in automatic cut to length machine manufacturing and strict quality control, KINGREAL STEEL SLITTER is your ideal automatic cut to length line manufacturer and supplier. KINGREAL STEEL SLITTER also provides excellent after-sales service to ensure that customer needs are fully met.

|

Minimum and Maximum Weight |

5 tons – 35 tons |

|

Minimum and Maximum Width |

550 mm to 2500 mm |

|

Minimum and Maximum Thickness |

0.3 mm to 20 mm |

|

Machine Speed |

0-20-60-80 m/min |

|

Raw Materials Used |

Hot-rolled steel / Cold-rolled steel / Stainless steel / Galvanized steel / Color-coated steel |

|

Automation Level |

Fully automatic |

|

Type |

2-roll, 4-roll, 6-roll leveling machine |

● KINGREAL STEEL SLITTER automatic cut to length machine uses coil feeding and AC servo drive.

● Equipped with a full-length CNC system to ensure rapid coil positioning.

● Hard chrome plated surface, durable and wear-resistant.

● Fully automatic cut to length line, requiring only one operator.

● Higher length and diagonal accuracy

● High-speed operation, with speeds up to 80m/min.

|

|

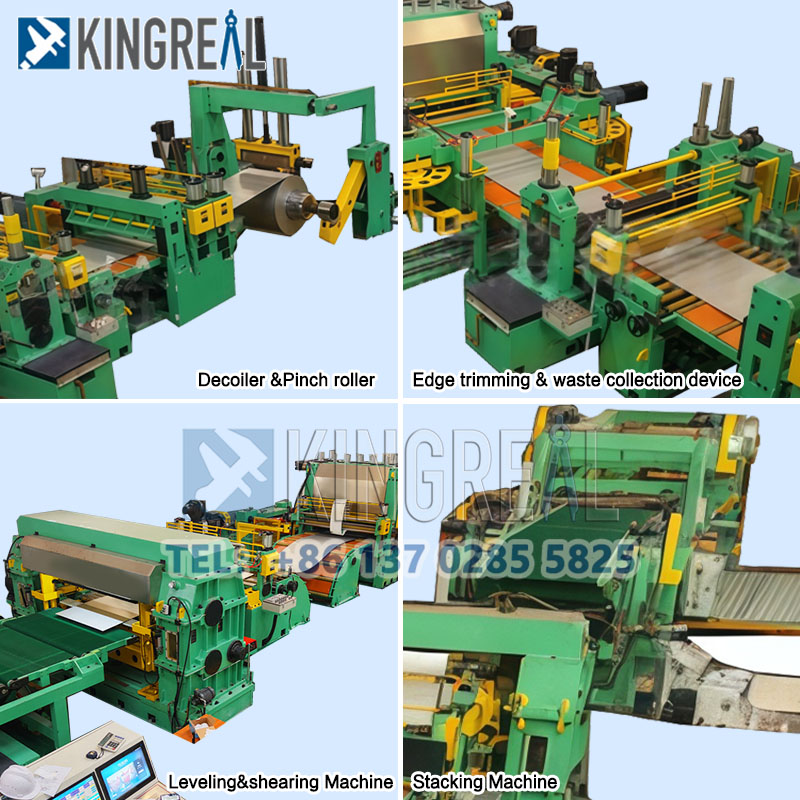

1. Decoiler for automatic cut to length line

KINGREAL STEEL SLITTER automatic cut to length machine is equipped with a high-efficiency decoiler that can automatically unroll the coil, greatly improving work efficiency. For further automation, users can also choose to equip the automatic cut to length machine with a feeding trolley. This trolley is driven by a motor and can move flexibly back and forth on the track, simplifying the operation of loading the coil onto the decoiler and making the production process smoother.

2. Leveling machine for automatic cut to length machine

KINGREAL STEEL SLITTER automatic cut to length machine features leveling machines with various designs, including two-roll, four-roll, and six-roll types, to fully meet the straightening needs of different materials and thicknesses. The rollers can be adjusted manually, hydraulically, or by motor. The hardened rollers have a hardness of HRC 55-60, ensuring good wear resistance and long-term reliability, maintaining efficient and stable operation even in high-intensity production environments.

3. Cutting unit for automatic cut to length line

The cutting unit is the core part of the fully automatic cut to length line, mainly used to cut the coil into plates of the required length. KINGREAL STEEL SLITTER offers a variety of shearing methods, including fly shearing, rotary shearing, swing shearing, and fixed shearing, which can be selected according to the user's specific needs. The flexibility of these cutting methods allows users to accurately control the cutting process, improve production efficiency, and ensure product quality.

4. Stacking unit for automatic cut to length machine

To further enhance production efficiency, KINGREAL STEEL SLITTER automatic cut to length lines are equipped with a stacking unit that organizes and stacks metal sheets. By reducing manual intervention, the stacking unit not only lowers labor costs and saves time but also ensures the neatness and standardization of the final product, facilitating subsequent transportation and use.

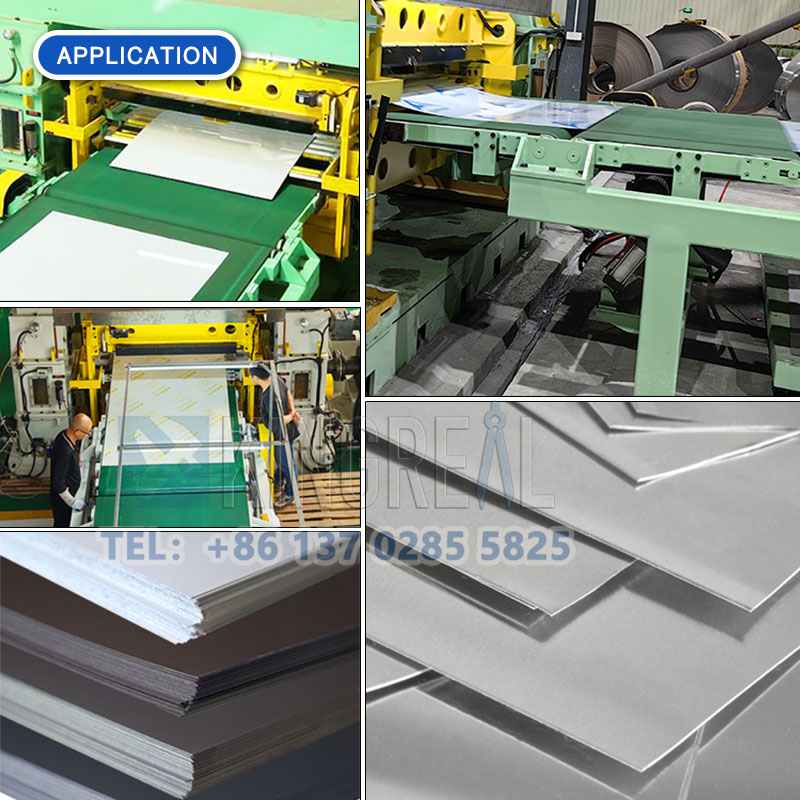

Automatic Cut to Length Line -- Ensure Quality of Metal Sheet

The fully automatic cut to length machine utilizes an intelligent PLC system to achieve precise, stable, and accurate cutting, thus ensuring product quality. Typically, the automatic cut to length line can achieve high-precision, burr-free edges, meeting the market's stringent product requirements. KINGREAL STEEL SLITTER quality control runs throughout the entire production process, including straightening and leveling to eliminate the deformation memory of the coil material. In addition, the automatic cut to length machine is equipped with precise sensors to control feeding, and a laminating device is used to meet customer requirements for material surface smoothness, ensuring the perfect performance of the final product.

|

1. Customer visit KINGREAL STEEL SLITTER welcomes all customers to visit the factory to see KINGREAL STEEL SLITTER automatic cut to length lines. This is the most convenient way to understand the actual performance of the automatic cut to length machines and evaluate whether KINGREAL STEEL SLITTER products meet the customer's project needs. At the factory, KINGREAL STEEL SLITTER professional staff will accompany customers throughout the visit, demonstrating the automatic cut to length line's operation and the finished products it produces, and promptly answering any questions. |

|

|

2. Customized automatic cut to length line solution design KINGREAL STEEL SLITTER will delve into customer needs to provide customized automatic cut to length machine solutions. KINGREAL STEEL SLITTER design team will professionally tailor the most suitable fully automatic cut to length line manufacturing solution for each customer, ensuring that every detail meets the customer's production requirements. |

|

3. Automatic cut to length line manufacturing KINGREAL STEEL SLITTER manufacturing team strictly follows the process to manufacture the automatic cut to length machines in the factory. From the selection of raw materials to the production of each component, every link is strictly controlled to ensure high quality and reasonable price. |

|

|

4. Automatic cut to length line acceptance Once the automatic cut to length machine manufacturing is completed, KINGREAL STEEL SLITTER will invite the customer to come for acceptance. If the customer is unable to attend, KINGREAL STEEL SLITTER staff can perform the acceptance on their behalf. The automatic cut to length line will only be shipped after receiving customer confirmation to ensure customer satisfaction. |

|

5. Automatic cut to length line delivery The KINGREAL STEEL SLITTER team will meticulously pack all components of the automatic cut to length machine and ship them to the customer's designated factory within the specified time-frame. KINGREAL STEEL SLITTER ensure the automatic cut to length line arrives in perfect condition and on time, providing the most timely support for our customers' projects. |

|

|

6. On-site automatic cut to length machine installation KINGREAL STEEL SLITTER provides automatic cut to length line installation and operation training for our customers. KINGREAL STEEL SLITTER professional engineers will travel to the customer's factory for final automatic cut to length machine installation and commissioning, and provide detailed training to operators to ensure the machine operates safely and efficiently. |

If you are looking for an automatic cut to length machine solution, whether for processing different materials such as steel, stainless steel, aluminum, or copper, or requiring an automatic cut to length line capable of handling different material thicknesses, KINGREAL STEEL SLITTER is your ideal choice. KINGREAL STEEL SLITTER professional team will fully understand your needs and provide corresponding automatic cut to length machine manufacturing solutions.

To date, KINGREAL STEEL SLITTER has successfully collaborated with customers on multiple automatic cut to length line projects in Indonesia, Russia, and other regions. Contact KINGREAL STEEL SLITTER today to learn more!