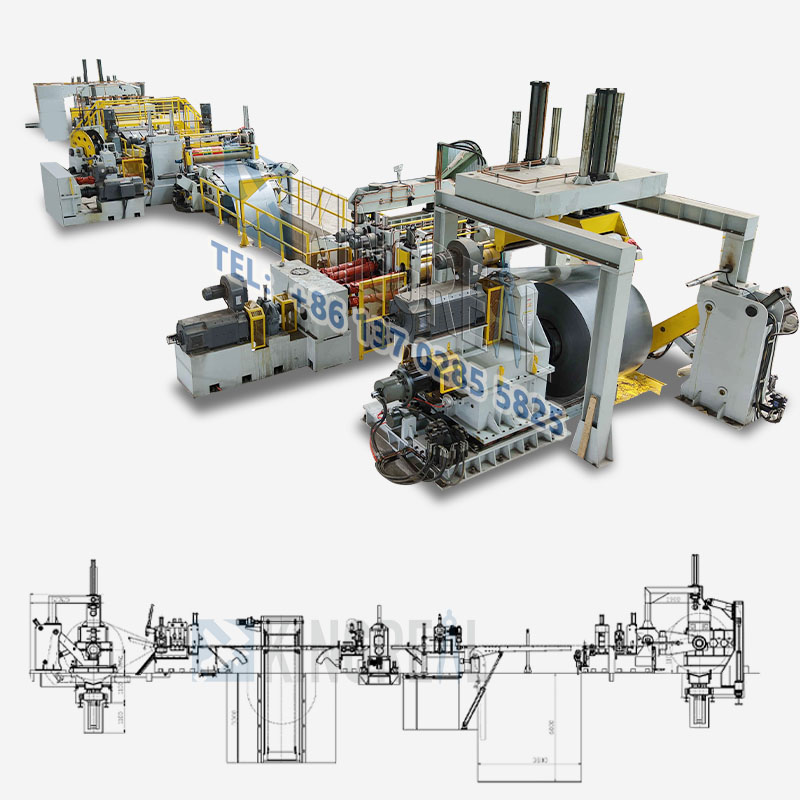

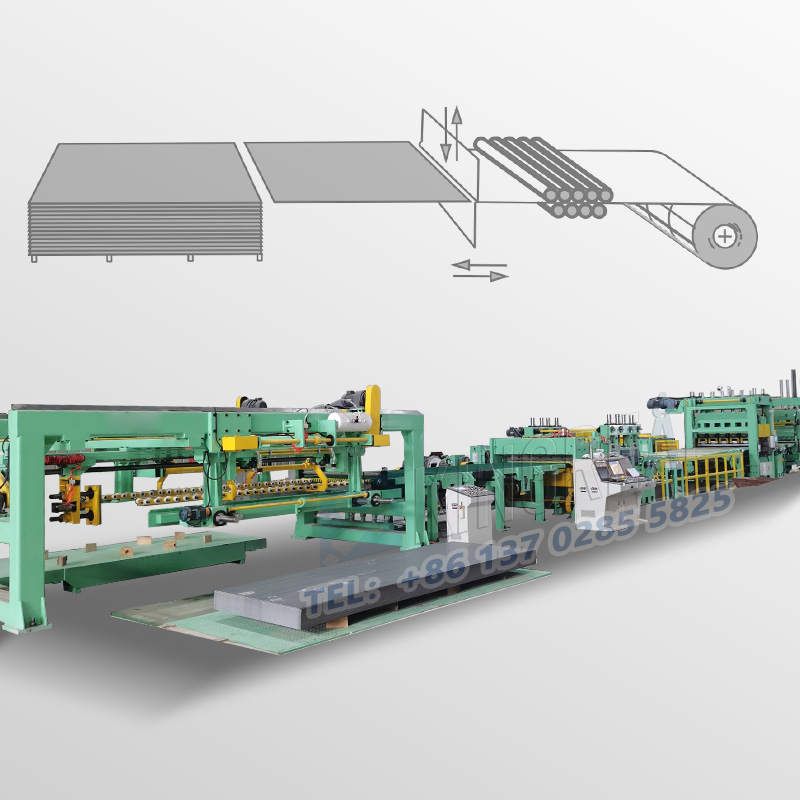

Coil processing equipment is used for processing metal materials. The main functions of this coil processing line include uncoiling, straightening, feeding, punching, slitting, and length cutting—indispensable processes in metal processing. Through these processes, raw materials can be effectively transformed into production-ready shapes and sizes to meet the requirements of various manufacturing processes.

KINGREAL STEEL SLITTER designs and manufactures a full range of coil processing equipment, including metal slitting machine, metal cut to length line, metal perforated machine, metal leveling machine, decoiler, and feeder. To better serve customers, KINGREAL STEEL SLITTER also provides customized designs based on specific customer needs and material characteristics, ensuring that the coil processing equipment can adapt to applications requiring high strength and demanding surface finishes. Whether for large-scale industrial production or small-scale factories, coil processing equipment provides efficient and reliable solutions for the metal processing industry.

|

|

|

|

|

|

Coil processing equipment offers several advantages. First, it can process various types of metal materials, including stainless steel, steel, silicon steel, carbon steel, aluminum, copper, and PPGI. This versatility allows different industries greater flexibility in material selection, thus improving production adaptability. Furthermore, coil processing line provides lean manufacturing solutions, effectively reducing waste and increasing production efficiency. Through advanced automation technology, KINGREAL STEEL SLITTER coil processing line is not only highly efficient but also user-friendly, simplifying procedures and enabling workers to perform various processes more easily. This flexibility and ease of use allows companies to quickly respond to market demands and dynamically adjust production plans.

More importantly, KINGREAL STEEL SLITTER coil processing equipment can be designed to meet specific customer needs, such as in leveling, fixed-length cutting, or slitting. Different coil processing line produces different results and final products, allowing customers to choose the most suitable coil processing equipment based on their requirements. Additionally, coil processing equipment can be integrated with other roll forming machines to form a complete production line, achieving a higher level of automation and efficiency.

Coil processing line, as an important metalworking tool, has a wide range of applications, meeting the diverse metal processing needs of various industries, including metal processing, automotive, home appliance manufacturing, furniture manufacturing, aerospace, electronics manufacturing, and stamping plants. This means that coil processing line is not limited to a specific field but can support the needs of various industries. In the automotive industry, materials processed by coil processing line are used to manufacture body structural parts and components, ensuring the cutting and processing precision of materials during production. In home appliance manufacturing, materials processed by coil processing equipment also provide necessary metal parts for appliances such as refrigerators and washing machines. Furthermore, the furniture manufacturing industry has also benefited from improved quality and efficiency due to the adoption of coil processing equipment, enabling the rapid production of high-quality metal furniture parts. The aerospace industry has extremely high requirements for quality and safety; through high-precision cutting and forming, coil processing line ensures that every aerospace part meets stringent standards.

KINGREAL STEEL SLITTER has a professional level of technology and production capacity in coil processing equipment, which can be customized according to the customer's production needs. Customers are welcome to send their production requirements or product images to KINGREAL STEEL SLITTER, which will provide customized solutions!

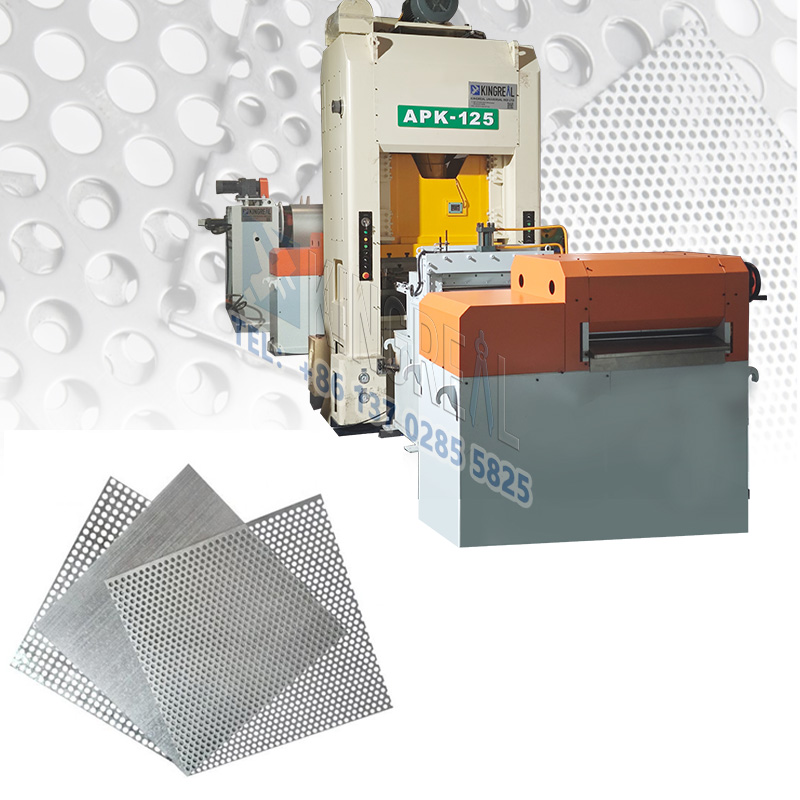

KINGREAL STEEL SLITTER Sheet Coil Perforation And Rewind Machines are used to unwind, flatten, punch, and rewind metal coils of various materials. KINGREAL STEEL SLITTER coil to coil perforation lines have earned wide acclaim in the metalworking industry for their high speed and precision.

KINGREAL STEEL SLITTER metal ceiling tile perforation line can process metal coils of different materials and thicknesses. This metal ceiling tile perforation line can be used in conjunction with the metal ceiling tile production line to efficiently produce metal perforated ceiling tiles of different types and sizes.

KINGREAL STEEL SLITTER High speed Coil Perforation Production Line can produce various specifications of perforated ceilings such as 300x300mm, 600x600mm, 1200x600mm, etc., which are widely used in decoration projects.

KINGREAL STEEL SLITTER Full Automatic Perforated Metal Production Line can be used in conjunction with a metal ceiling tile production line to produce high-precision perforated ceilings. This metal ceiling tile perforation line is characterized by efficient production, precise punching, and stable operation.

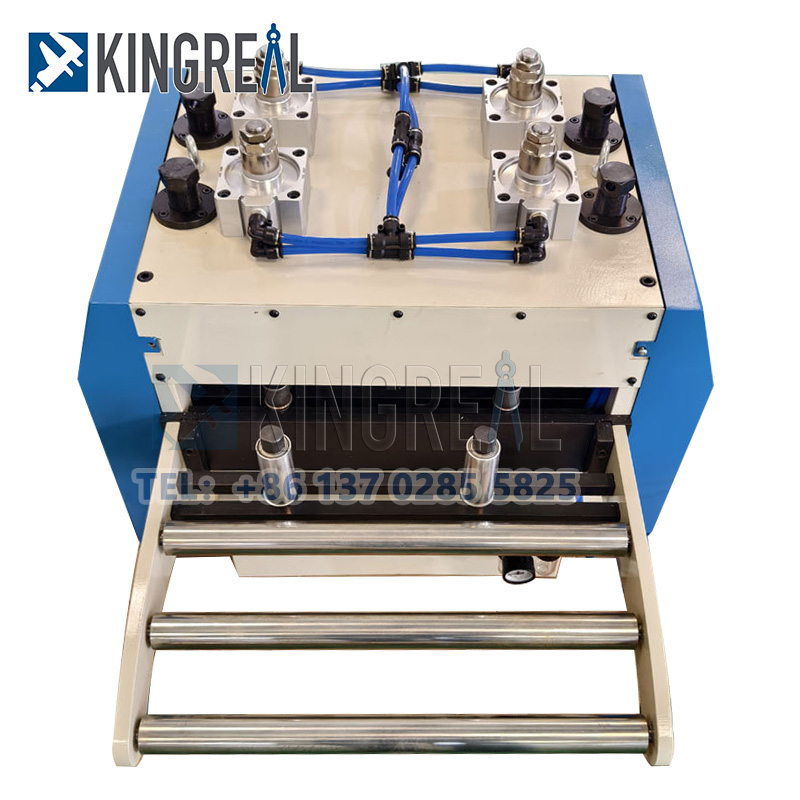

KINGREAL STEEL SLITTER Middle-Plate Decoiler Levelling Feeder Machine is suitable for stamping and leveling feeding of medium plate coils, with the advantages of high specific feeding accuracy and small cumulative error. As a professional manufacturer of feeder equipment, KINGREAL STEEL SLITTER has more than 20 years of production and sales experience. Can provide customers with the best solution.

As a manufacturer in the field of automatic feeding machines, KINGREAL STEEL SLITTER can provide Thick-Plate Decoiler Straightener Feeder Machine. The equipment is specially designed for materials with a thickness of 0.6-6mm. It has comprehensive functions and compact structure.