The medium gauge cut to length line is a device specifically designed for precise cutting of metal coils with a thickness range of 0.3 to 6 mm. The design of this medium gauge cut to length machine fully considers the production needs of customers and provides a variety of shearing methods, including flying shearing cut to length line, swing shearing cut to length line, rotary shearing cut to length line and fixed shearing cut to length line. This article will discuss in detail the uses, main components, advantages and common problems of the medium gauge cut to length machine.

1. Precision cutting for medium gauge cut to length machine

The medium gauge cut to length line can accurately cut metal coils according to the length preset by the customer. This accuracy not only improves production efficiency, but also reduces the waste of raw materials and ensures that the size of each plate meets production requirements.

2. Multiple material processing for medium gauge cut to length machine

The medium gauge cut to length line can handle a variety of metal materials, including carbon steel, stainless steel, aluminum alloy, copper, etc., to meet the production needs of different customers. Whether it is thin or thick plates, the medium gauge cut to length machine can provide stable performance.

3. Improve production efficiency for medium gauge cut to length line

Through automated design, the medium gauge cut to length machine significantly improves production efficiency. Traditional manual feeding and cutting methods are often time-consuming and prone to errors, while the fully automated operation of the medium gauge cut to length line can quickly complete multiple batches of production tasks.

4. Adapt to multi-specification production for medium gauge cut to length line

The medium gauge cut to length machine has flexible shearing parameter settings, which can be adjusted according to customer needs to adapt to multi-specification production. Whether it is large-scale production or small-batch customization, the medium gauge cut to length line can easily cope with it.

|

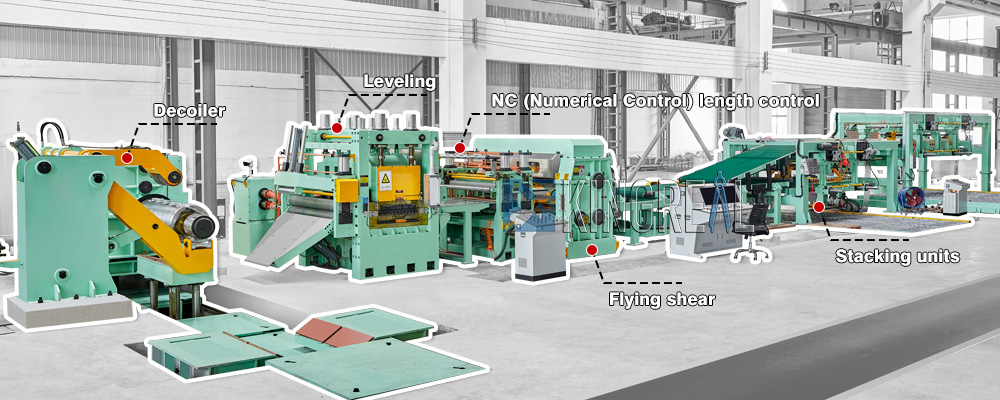

Decoiler for medium gauge cut to length machine The decoiler is the first process of the medium gauge cut to length line, responsible for unrolling large coils of metal coils. The metal coils are gradually unrolled on the decoiler, ready to enter the subsequent processing links. |

|

|

Leveling machine for medium gauge cut to length machine The leveling machine is used to level the plate to eliminate bends and defects. For customers with high flatness requirements, KINGREAL STEEL SLITTER can equip the medium gauge cut to length line with two levelers to ensure that the metal coils undergo two leveling processes before shearing, thereby maximizing the surface flatness. |

|

|

Feeding system for medium gauge cut to length machine The leveled plate is fed into the shearing unit through an automatic feeding device. The automated feeding system not only increases the speed, but also reduces the errors caused by manual operation. |

|

|

Cutting unit for medium gauge cut to length line The cutting unit is the core part of the medium gauge cut to length machine, which is responsible for cutting the plate into the required length according to the preset size. Customers only need to enter the finished product parameters on the control panel, and the medium gauge cut to length line can automatically perform the corresponding shearing, flexibly meeting the production needs of multiple specifications. |

|

|

Stacking system for medium gauge cut to length machine The cut plates are neatly stacked on the automatic stacking table, ready for further processing or transportation. The automated design of the system greatly improves production efficiency while ensuring the quality of the finished product. |

|

|

1. Medium gauge cut to length machine with strong processing capacity The medium gauge cut to length line can handle metal coils with a maximum thickness of 6 mm, a maximum width of 2000 mm, and a maximum weight of 40 tons, which can meet the needs of most customers on the market. If customers have special production requirements, KINGREAL STEEL SLITTER is happy to provide customized solutions based on drawings and needs.

2. Precision-cutting medium gauge cut to length machine The medium gauge cut to length line is equipped with high-hardness blades to ensure that each plate is cut to a precise length, minimizing errors. The durability of the blades ensures the shearing accuracy of the metal sheet, so that each finished product meets strict quality standards. |

|

|

3. Personalized medium gauge cut to length machine manufacturing solutions KINGREAL STEEL SLITTER can provide personalized medium gauge cut to length line manufacturing solutions according to the production needs of different customers. For example, high-speed medium gauge cut to length machines are provided for customers with high requirements for production efficiency, compact cut to length lines are provided for customers with small factory footprints, and even customized heavy gauge cut to length lines are provided for customers who need to process 20 mm thick metal coils.

4. Simple maintenance for medium gauge cut to length line The design of the medium gauge cut to length machine takes into account the convenience of operation and maintenance. The various parts of the equipment are easy to access and clean, and regular maintenance can greatly extend the service life of the equipment and ensure its long-term and efficient operation. |

|

1. What materials can medium gauge cut to length machines process?

The medium gauge cut to length line can process a variety of metal materials, including steel, aluminum, stainless steel, copper, etc., and adapt to metals of different thicknesses.

2. What is the difference between a medium gauge cut to length machine and a metal slitting machine?

Medium gauge cut to length lines are mainly used for horizontal cutting of large metal coils, while metal slitting machines cut coils into narrow strips longitudinally, so the application scenarios and operation methods of the two are different.

3. Can medium gauge cut to length machines meet customized length requirements?

Yes, medium gauge cut to length lines usually support design according to specific requirements and can cut plates into customized lengths to meet the needs of different customers.

4. What maintenance is required for medium gauge cut to length machines?

Regular cleaning, inspection and replacement of parts are the key to keeping medium gauge cut to length lines running efficiently. Regular maintenance can effectively extend the service life of the medium gauge cut to length machine and ensure its stable performance.