Aluminum coil slitting line is a kind of equipment specially used to unwind, slitting and rewind metal coils (including aluminum strips) into strips of required width. It is widely used in the metal processing industry, especially in the field of aluminum strip processing. The following is a detailed introduction to the aluminium coil slitting machine.

|

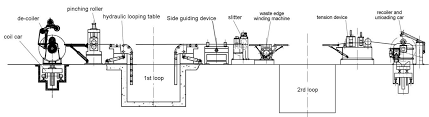

Unwinding, material placement, slitting, and rewinding are the main processes of the aluminum coil slitting machine's operation. First, the unwinding apparatus positions the aluminum coil to be processed on the unwinding device, then it unfolds it. The material positioning mechanism guides the unfolded aluminum coil for accurate cutting to the slitting and slitting area. Once the cutting is finished, the cut aluminum strip is fed into the recoiler and rolled.

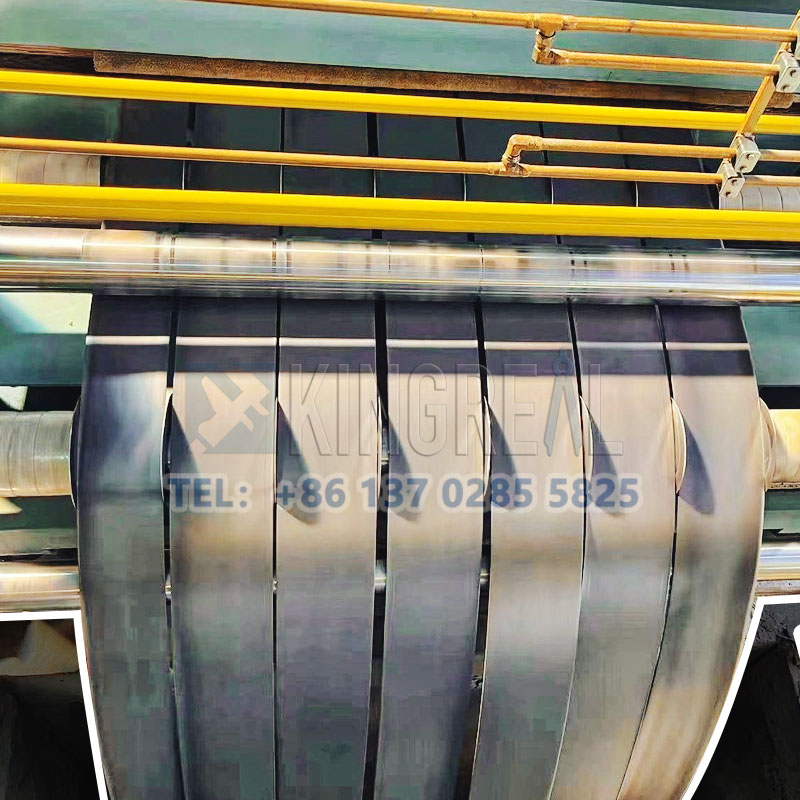

Advanced cutting techniques, including high-precision blades and high-strength pressure wheels, are used by the aluminium coil slitting line during the slitting process to guarantee cutting stability and precision. Simultaneously, to satisfy various processing needs, the aluminium coil slitting machine also has an advanced control system that can real-time monitor and alter cutting parameters including cutting width, cutting speed, and cutting depth. |

|

|

The main structure of the aluminium coil slitting machine includes unwinding device, material guiding and positioning device, slitting and slitting device and rewinding device. Among them, the unwinding device is responsible for unwinding the aluminum strip; the material guiding and positioning device is used to guide the aluminum strip into the slitting and slitting area; the slitting and slitting device is responsible for cutting the aluminum strip into strips of the required width; the rewinding device rewinds the cut aluminum strip into a roll.

In addition, the aluminium coil slitting line is also equipped with an electronic control system and a transmission system. The electronic control system controls the operation of the entire aluminium coil slitting machine through devices such as controllers, servo motors, encoders and touch screens to ensure that each part works smoothly and stably. The transmission system drives each device through servo motors, reducers, sprockets and chains to realize the functions of unwinding, slitting and rewinding the aluminum strip. |

|

According to the different production needs of customers, there are many types of aluminium coil slitting machines on the market. For example, according to the different thickness requirements of the metal coils to be processed by customers, KINGREAL STEEL SLITTER has designed light gauge slitting machines, medium gauge slitting machines and heavy gauge slitting machines. The light gauge slitting machine can process metal coils with a thickness range of 0.2-3mm; the medium gauge slitting machine can process metal coils with a thickness range of 3-6mm; the heavy gauge slitting machine can process metal coils with a thickness range of 6-16mm. In addition, in order to meet the customized needs of customers, KINGREAL STEEL SLITTER also designs belt tension aluminium coil slitting lines, high-speed slitting machines and Dual slitter head coil slitting machines for customers.

|

|

|

|

Aluminum coil slitting machines are widely used in the aluminum strip processing industry, especially in construction, transportation, packaging and other fields. It can accurately cut and process aluminum strips to meet the diverse needs of aluminum strip materials in different fields. For instance, in the field of construction, aluminum coil slitting lines can slice aluminum strips into strips of different widths to meet requirements for making aluminum alloy doors and windows, curtain walls, and other building materials; in the field of transportation, aluminum coil slitting lines can cut aluminum strips into strips of specific sizes for manufacturing automotive bodies, carriages, and other components; in the field of packaging, aluminum coil slitting lines can cut aluminum strips into packaging materials of various shapes to satisfy many needs.

With the continuous advancement of science and technology and the continuous development of the aluminum strip processing industry, aluminium coil slitting lines are also constantly innovating and upgrading. In the future, aluminium coil slitting machines will develop in a more intelligent, automated and efficient direction. For example, some advanced aluminium coil slitting lines have been equipped with intelligent control systems and machine vision systems, which can realize functions such as automatic adjustment of cutting parameters, automatic detection and correction of errors; at the same time, the transmission system and cutting technology of the equipment are also being continuously optimized and improved to improve cutting accuracy and efficiency.

In addition, with the continuous improvement of environmental awareness and the popularization of green production concepts, aluminium coil slitting machines will also pay more attention to environmental protection and energy saving. In the future, aluminium coil slitting lines will be manufactured and used with more environmentally friendly materials and processes to reduce pollution and damage to the environment.

If you are interested in aluminium coil slitting machines and want to get more relevant information, please consult KINGREAL STEEL SLITTER! We have a 24-hour online professional team to provide you with professional machine problem answers.