KINGREAL STEEL SLITTER is a professional manufacturer of metal cut to length machines. With the advantages of integrating design, R&D, manufacturing and sales, it can provide customers with high-quality metal cut to length lines and ensure on-time delivery. So far, KINGREAL STEEL SLITTER metal cut to length machines have been successfully sold to customer factories in Russia, Algeria, Turkmenistan, Turkey, Canada, the United States, Malaysia and other countries.

This article will share five real metal cut to length line transaction cases, hoping to give you a deeper understanding of KINGREAL STEEL SLITTER metal cut to length machines. If you have a purchase demand for metal cut to length lines or want to know more about the parameters, please feel free to consult KINGREAL STEEL SLITTER!

Customer background:

This German customer is from the metal processing industry and has very strict requirements for metal cut to length machines. He hopes that the metal cut to length line can cut quickly and with high precision, and can handle a variety of metal materials, such as stainless steel, copper, aluminum, etc. The customer expects KINGREAL STEEL SLITTER to provide a metal cut to length machine that is compatible with a variety of materials to meet his production needs.

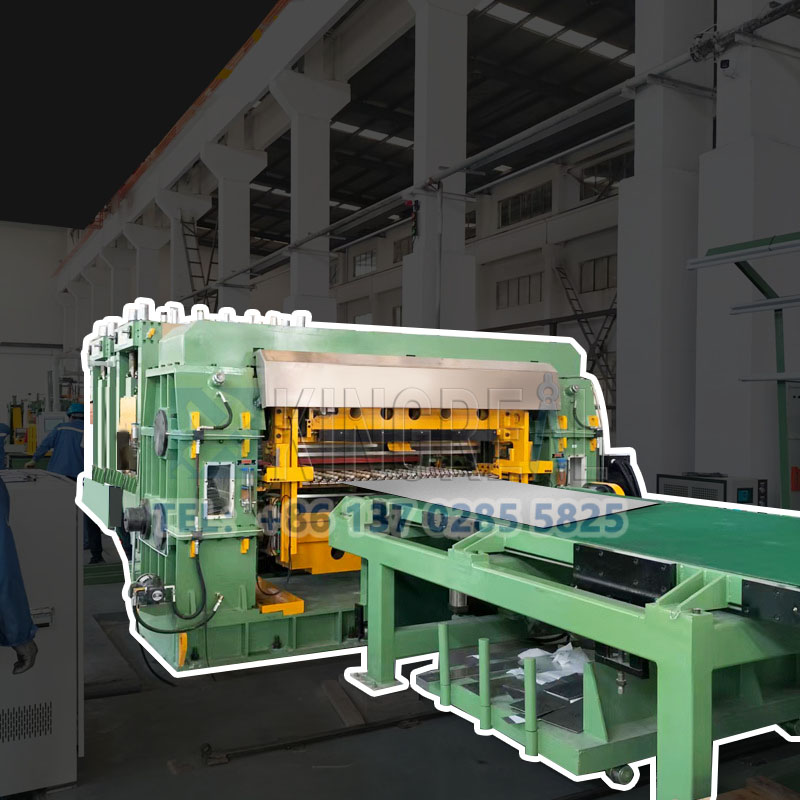

Features of metal cut to length line

KINGREAL STEEL SLITTER designed a flying shearing cut to length line according to German customer needs. The unique feature of this Flying shearing cut to length line is that the flying shear can accelerate and synchronize with the feeding speed of the strip, and can cut without stopping the feeding. This means that the Flying shearing cut to length line can process a whole roll of strip without stopping for the shearing cycle, which greatly improves production efficiency.

|

|

|

Manufacturing Difficulty of flying shearing cut to length line

The difficulty of the flying shear design lies mainly in how to achieve the perfect combination of high-speed operation and high-precision shearing. In order to improve the shearing accuracy, KINGREAL STEEL SLITTER uses an advanced control system to ensure that the shearing error is controlled within the minimum range under high-speed operation. In addition, the difficulty of the design compatible with multiple materials lies in the differences in the processing characteristics of different metal materials. KINGREAL STEEL SLITTER solved this problem through fine parameter adjustment and material adaptation.

Customer Background:

This Russian customer is from the heavy industry industry. The metal coils he processes are relatively thick, and many conventional metal cut to length lines on the market cannot meet his needs. He needs a metal cut to length machine that can process thick plates and improve production safety while ensuring quality.

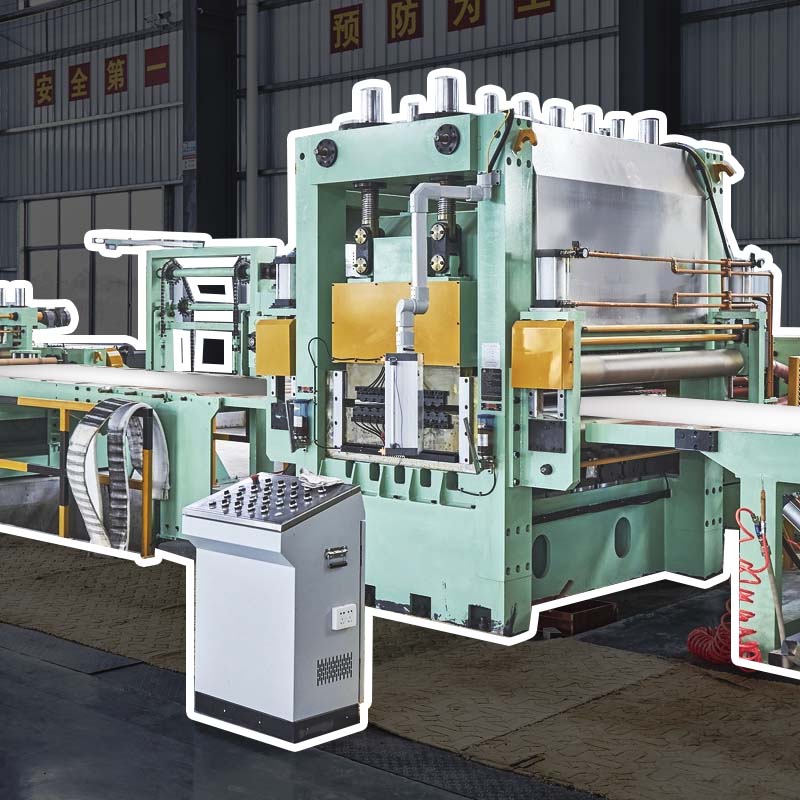

Features of metal cut to length line

The Heavy gauge cut to length line designed by KINGREAL STEEL SLITTER can process metal coils with a thickness of 6-20mm. According to the Russian customer's requirements, the Heavy gauge cut to length line is equipped with a protective shield, which can fully protect the workers during operation and prevent them from being injured by accidentally touching the machine parts. This design not only improves the safety of the Heavy gauge cut to length line, but also enhances the workers' sense of security.

|

|

|

Manufacturing Difficulty of Heavy gauge cut to length line

The difficulty of manufacturing the Heavy gauge cut to length line lies in how to ensure the stability and shearing accuracy of the equipment when processing high-thickness metal coils. At the same time, the design of the protective shield also faces challenges, which need to ensure safety while not affecting the performance and operation of the Heavy gauge cut to length line. KINGREAL STEEL SLITTER ensures the reasonable layout of the protective shield through meticulous engineering design, so that it can effectively protect the workers without hindering the normal operation of the Heavy gauge cut to length line.

Customer Background:

The production requirements of Spanish customers are large-scale manufacturing, and they expect the metal cut to length machine to work continuously for more than 20 hours. They need an efficient metal cut to length line to meet the needs of fast shearing.

Features of metal cut to length machine

The maximum production speed of KINGREAL STEEL SLITTER High speed cut to length line can reach 80m/min. In order to meet the special needs of Spain customers, the shearing system is equipped with a swing shear design, which can be processed without stopping the High speed cut to length line. This design greatly improves the continuous production capacity of the High speed cut to length line and ensures that customers will not encounter failures during long-term operation.

|

|

|

Manufacturing Difficulty of High speed cut to length line

The manufacturing difficulty of High speed cut to length line s lies mainly in how to achieve a balance between high-speed operation and shearing accuracy. In order to ensure that the machine can operate normally for a long time, KINGREAL STEEL SLITTER uses an efficient heat dissipation system and wear-resistant materials in the design to ensure that the equipment can maintain stable performance under high-intensity work.

Customer Background

Dutch customers mainly process thin metal coils. In order to avoid waste of resources, they hope to purchase a Light gauge cut to length line. At the same time, due to the special needs of the industry, they have high requirements for the flatness of metal coils.

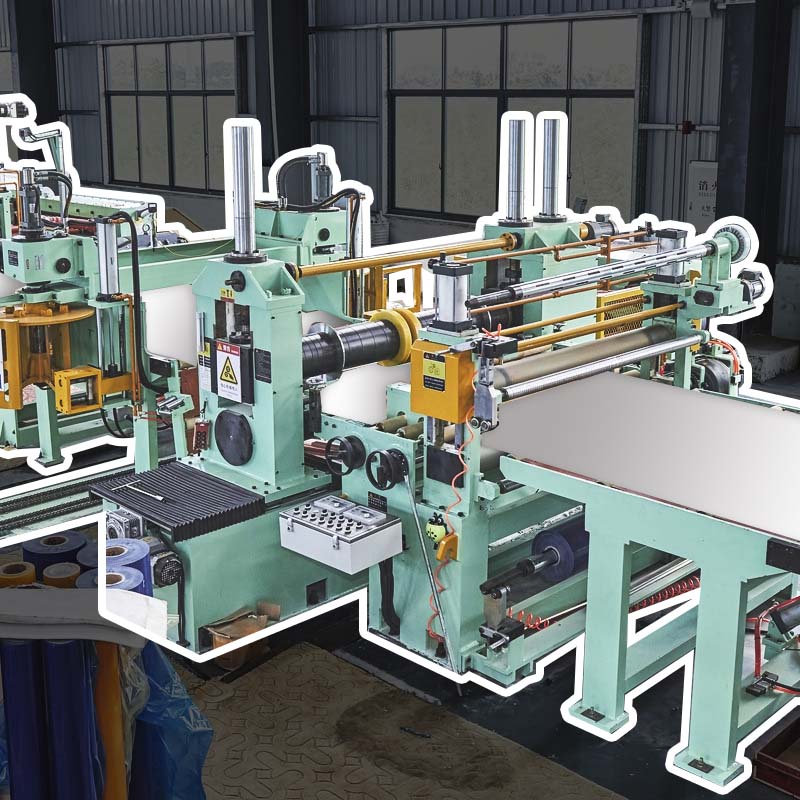

Features of metal cut to length machine

The Light gauge cut to length line designed by KINGREAL STEEL SLITTER for Dutch customers can process metal coils with a thickness of 0.3-3mm and is equipped with a double leveling machine. The metal coil undergoes two steps of leveling before cutting, which effectively improves the flatness of the metal surface and meets the high standards of customers.

|

|

|

Manufacturing Difficulty of Light gauge cut to length line

The manufacturing difficulty of Light gauge cut to length lines lies mainly in how to ensure the stability and accuracy of thin materials during the shearing process. Since thin plate materials are prone to deformation, KINGREAL STEEL SLITTER uses advanced leveling technology and a sophisticated shearing control system in the design to ensure the quality of the final product.

Customer background

The Canadian customer is a new entrant in the home appliance manufacturing industry and needs to process stainless steel and galvanized steel coils. Since they don’t know much about metal cut to length lines, they hope that KINGREAL STEEL SLITTER can provide a personalized metal cut to length line manufacturing solution based on their actual needs.

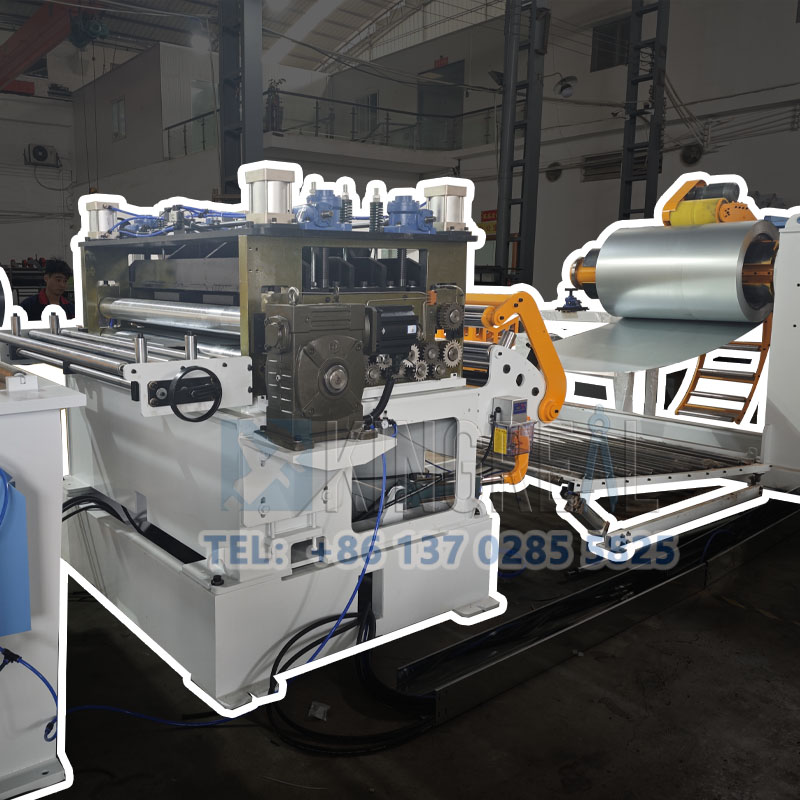

Features of metal cut to length machine

KINGREAL STEEL SLITTER recommended a rotary shearing cut to length line to the Canadian customer. This rotary shearing cut to length line is very suitable for the home appliance manufacturing industry and can accurately process stainless steel and galvanized steel coils. The automatic control and leveling mechanism of the rotary shear system ensures consistent shearing and is suitable for multiple industries such as automobiles, construction and home appliance manufacturing.

|

|

|

Manufacturing difficulty of rotary shearing cut to length line

The manufacturing difficulty of the rotary shear system lies mainly in how to ensure accuracy and efficiency during the shearing process. KINGREAL STEEL SLITTER uses advanced transmission systems and high-precision sensors in the design to ensure that each shearing can meet customer requirements, thereby ensuring the quality of the final product.