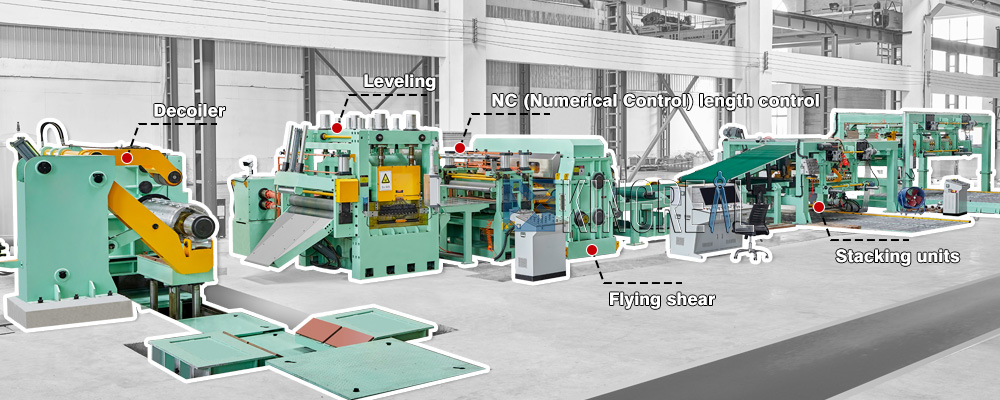

In 2025, KINGREAL STEEL SLITTER ushered in a milestone technological innovation - a comprehensive upgrade of the high speed cut to length line. This upgrade is not only a technological breakthrough, but also an important progress of KINGREAL STEEL SLITTER in the field of high speed cut to length machine, marking the further consolidation of KINGREAL STEEL SLITTER leading position in the high speed cut to length line manufacturing industry.

Through the preliminary preparation of KINGREAL STEEL SLITTER engineers, a new high speed cut to length machine was successfully developed and put into production. This high speed cut to length line innovation provides customers with a new solution for efficient production and cost control.

This newly launched high speed cut to length line adopts the internationally leading double-pointed shell-shaped blade design. When the metal coil passes through the cut to length machine, the blade can quickly cater for shearing, ensuring that the metal coil is accurately broken in a very short time.

This design not only improves the shearing speed and accuracy, but also improves the durability of the high speed cut to length machine and reduces the maintenance frequency.

The shearing speed of the high speed cut to length machine is several times that of traditional equipment. For high speed cut to length lines that require high output, this means that higher production efficiency can be achieved. The intelligence level of the high speed cut to length machine has also been greatly improved.

It is equipped with advanced sensors and intelligent algorithms, which can monitor various parameters in the production process, such as shearing pressure, speed and temperature in real time. Based on these data, the high speed cut to length line can make automatic adjustments to ensure the stability and reliability of the production process. This intelligent high speed cut to length machine design provides customers with more flexible production options.

By introducing high speed cut to length machines, KINGREAL STEEL SLITTER has not only improved production efficiency, but also achieved remarkable results in cost control. The continuous and fast shearing characteristics of the high speed cut to length line reduce dependence on manual labor, thereby reducing labor costs.

In addition, the precise shearing ability reduces metal coil waste and defective rates, further reducing production costs. For many companies, this means that higher output can be obtained with lower investment, greatly improving their market competitiveness.

The intelligent characteristics of the high speed cut to length machine bring significant advantages to quality control. Traditional shearing technology often relies on manual monitoring and is prone to human errors.

KINGREAL STEEL SLITTER high speed cut to length line can monitor various parameters in the production process in real time through an integrated intelligent system to ensure that each batch of metal coil meets strict quality standards. This process not only improves the stability and consistency of the product, but also provides customers with more reliable product guarantees.

In actual applications, the high speed cut to length machine can automatically identify and adjust the shearing parameters to ensure that every step in the production process runs in the best condition. This intelligent quality control allows customers to focus more on other core production links when using the KINGREAL STEEL SLITTER high speed cut to length line without worrying too much about product quality issues.

|

|

|

At present, this high speed cut to length machine has been successfully delivered to Aruba, and customers are highly satisfied with it. Customer feedback said that this high speed cut to length line has effectively promoted their intelligent and efficient production. Customers fully recognized and thanked KINGREAL STEEL SLITTER for the quality and service of the high speed cut to length machine.

They believe that with the continuous advancement of technology and the deepening of application, KINGREAL STEEL SLITTER high speed cut to length line will show its unique value in more fields and contribute to the high-quality development of more customers.

Customers' affirmation is not only a recognition of KINGREAL STEEL SLITTER technology, but also a high evaluation of the company's comprehensive strength.

In the future, KINGREAL STEEL SLITTER will continue to be committed to technological innovation and promote the high speed cut to length machine to play a positive role in a wider range of industry applications.

Looking ahead, KINGREAL STEEL SLITTER will continue to increase its investment in the research and development of high speed cut to length line, and plans to launch more and more powerful high speed cut to length machines to meet the needs of different customers.

As the industry's requirements for intelligent and automated production increase, KINGREAL STEEL SLITTER will keep up with market trends to ensure that its high speed cut to length line products always maintain a leading position in technology and services.

Globally, the metal processing industry faces huge opportunities for change. KINGREAL STEEL SLITTER realizes that only by continuous innovation can it remain invincible in the fierce market competition.

In the future, KINGREAL STEEL SLITTER will continue to pay attention to customer needs, combine market changes, and launch more intelligent and automated high speed cut to length machine solutions to help customers continue to move forward on the road of high-quality development.