High speed cut to length lines are very important for the current metalworking sector. Production efficiency and product quality have become more vital for producers as technology keeps developing. Hence, numerous producers are frantically trying to replace high speed cut to length machine with conventional, semi-automatic cut to length machines so as to raise product quality and output capacity.

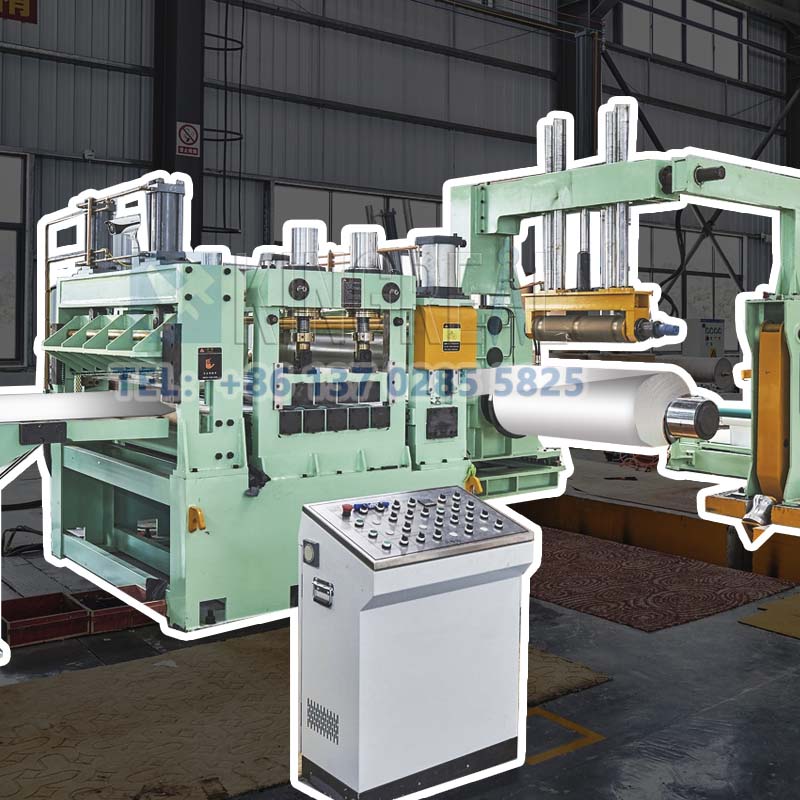

KINGREAL SLITTING, a major high speed cut to length line manufacturer, has given customers in several countries effective high speed cut to length machine solutions. Among these countries are Saudi Arabia, Qatar, Brazil, Russia, Indonesia, and the United States. Customers have given KINGREAL SLITTING whole praise for its thorough customer care, machine quality, and exactness of finished product.

To address common high speed cut to length machine issues in the market, KINGREAL SLITTING has implemented numerous technical optimizations and upgrades to ensure optimal performance and reliability of high speed cut to length lines.

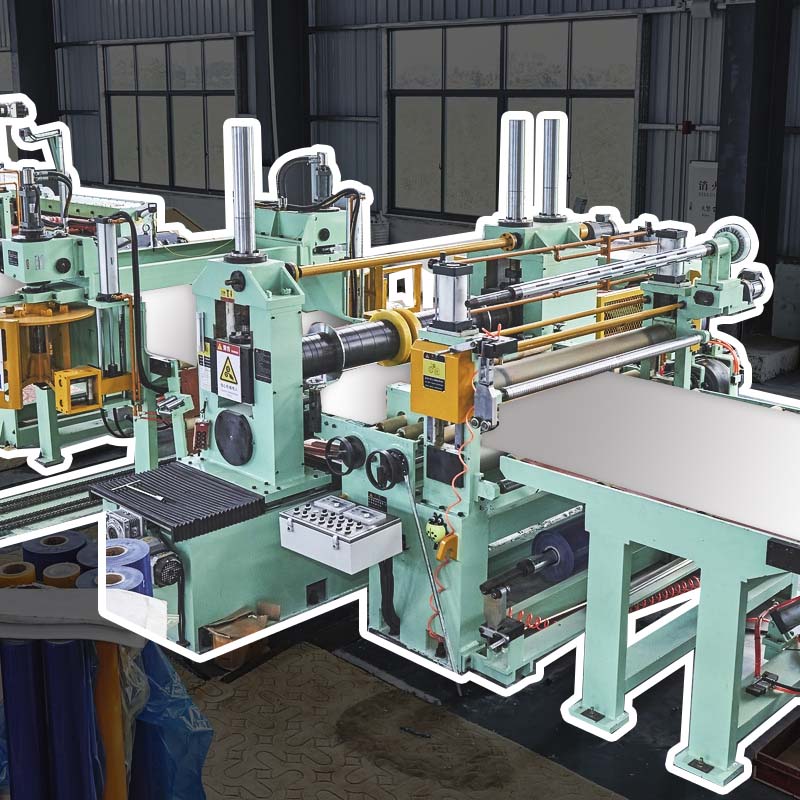

1. Pinch Roller Process Parameter Optimization

In a high speed cut to length machine, four pinch rollers are installed on each of the fixed and movable sides. The two sets of pinch rollers are connected by a synchronous shaft. The pinch rollers mostly hold the sheet metal shearable. If, on the other hand, the plate bends during the shearing process, the cut dimensions will be directly impacted and the shear quality will decrease. KINGREAL SLITTING solves this problem by precisely measuring and inspecting the inlet and outlet of the gripper to guarantee best synchronization, torque, and balance of the pinch rollers. By replacing rollers with diameters larger than the gripper's deflection and optimizing the pressure of the feed gripper, KINGREAL SLITTING effectively eliminates plate skew and misalignment during shearing, thereby improving the overall performance of the high speed cut to length line.

2. Designing a Blade Gap Compensation System

During the steel plate shearing process, the gap between the cut edges is determined by the plate thickness. Shearing defects can occur due to varying shearing conditions, temperatures, and equipment accuracy. To improve shearing quality, KINGREAL SLITTING designed a blade gap compensation system. Based on the condition of the plate being sheared, this mechanism automatically changes the blade gap to guarantee steady shearing. The system checks and changes the blade spacing in real time using a smart feedback mechanism to guarantee best shearing performance. This creative design helps the high speed cut to length machine to always produce excellent shearing results while working with steel plates of different thicknesses.

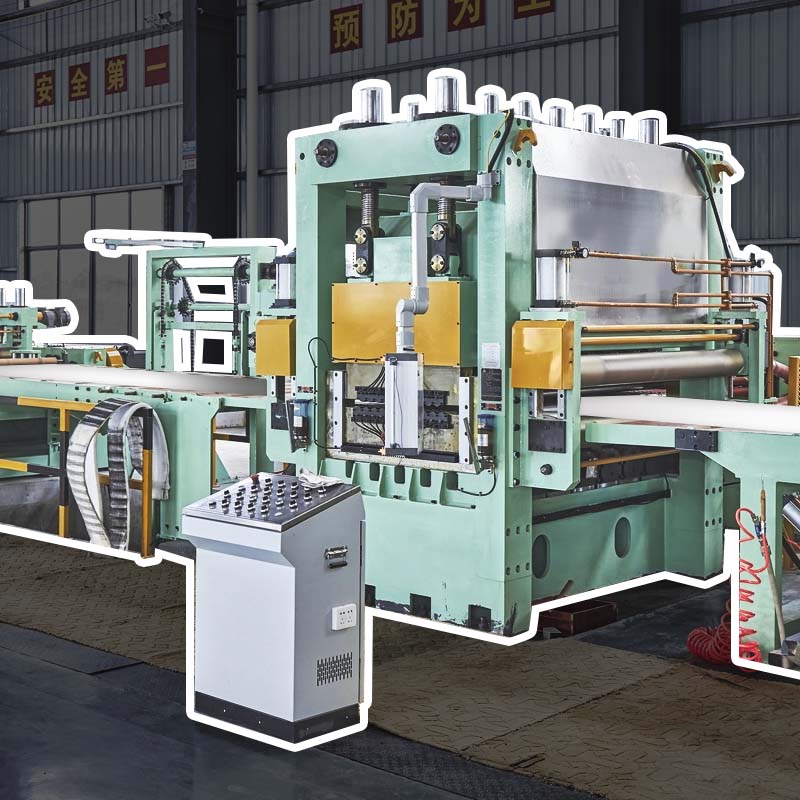

3. Analysis and Solutions for Tool-holder Parallelism

The parallelism of the shearing blades is crucial to shear quality. Factors such as tool-holder deformation and installation accuracy directly affect the quality of the cut edge. By precisely measuring the tool-holder end faces, KINGREAL SLITTING can identify deviations in parallelism and take appropriate measures. During routine maintenance, tool-holder repairs and adjustments are performed to ensure parallelism is within 0.2mm, significantly improving shear quality and reducing failure rates. KINGREAL SLITTING engineers utilize a keyless shrink-fit method during tool-holder installation, ensuring extremely high installation precision and preventing tool-holder deformation during long-term use.

In addition to the above measures, KINGREAL SLITTING engineering team continuously identifies and improves existing high speed cut to length line issues through market research, experience sharing with peers, and regular customer visits. This spirit of continuous innovation and upgrading has earned KINGREAL SLITTING the reputation of a "No.1 high speed cut to length machine manufacturer" among its customers.

|

|

|

1.Improved Production Efficiency

High speed cut to length machines have a top output rate of 80 m/min. High speed cut to length machine can finish more shearing jobs in less time than conventional cut to length lines, therefore minimizing wait and Increasing overall production capacity by means of downtime.

2.Improving Product Quality

The high speed cut to length line's sophisticated design and advanced technology ensure high-quality output during the shearing process. During shearing, the high speed cut to length machine keeps a constant shearing force and precise blade gap, hence minimizing flaws brought on by incorrect shearing. and raising finished product quality uniformity.

3.Strong Adaptability

Modern high speed cut to length lines are highly adaptable and can handle steel plates of varying thicknesses and materials. KINGREAL SLITTING typically provides high speed cut to length machines that can handle stainless steel, aluminum, copper, hot-rolled, cold-rolled, and other metal coils with thicknesses ranging from 0.2mm to 25mm. To meet diverse production needs, the high speed cut to length line can flexibly adjust shearing parameters to ensure efficient production of a wide range of products.

4.Reducing Labor Costs

The high speed cut to length machine operates automatically by simply entering production parameters on the PLC control panel. KINGREAL SLITTING also equips the high speed cut to length line with a stacking table that automatically stacks and collects the sheets. This minimizes human involvement throughout the entire production process, reducing labor costs for customers.