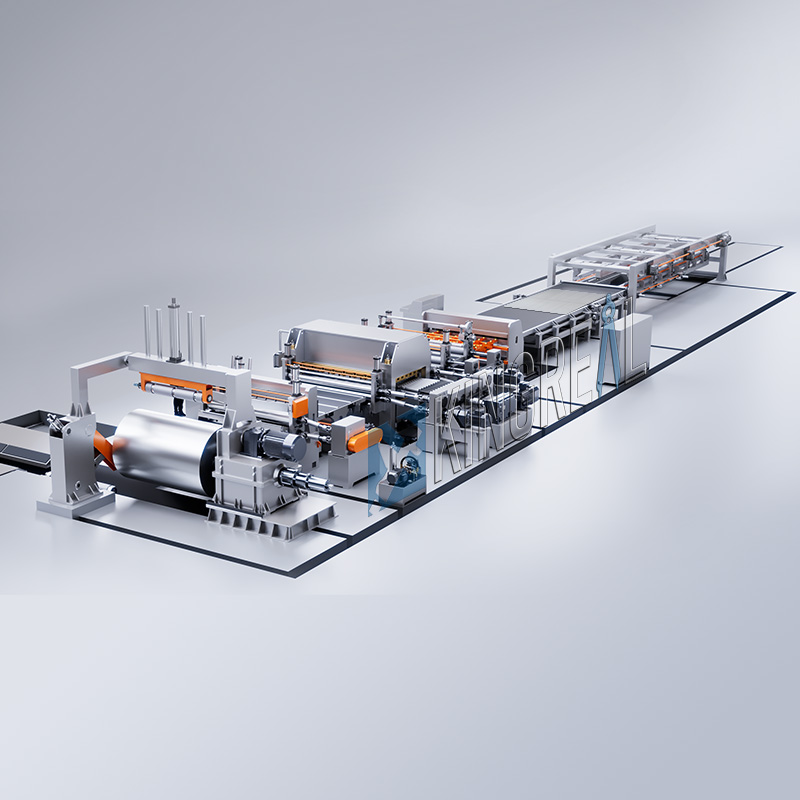

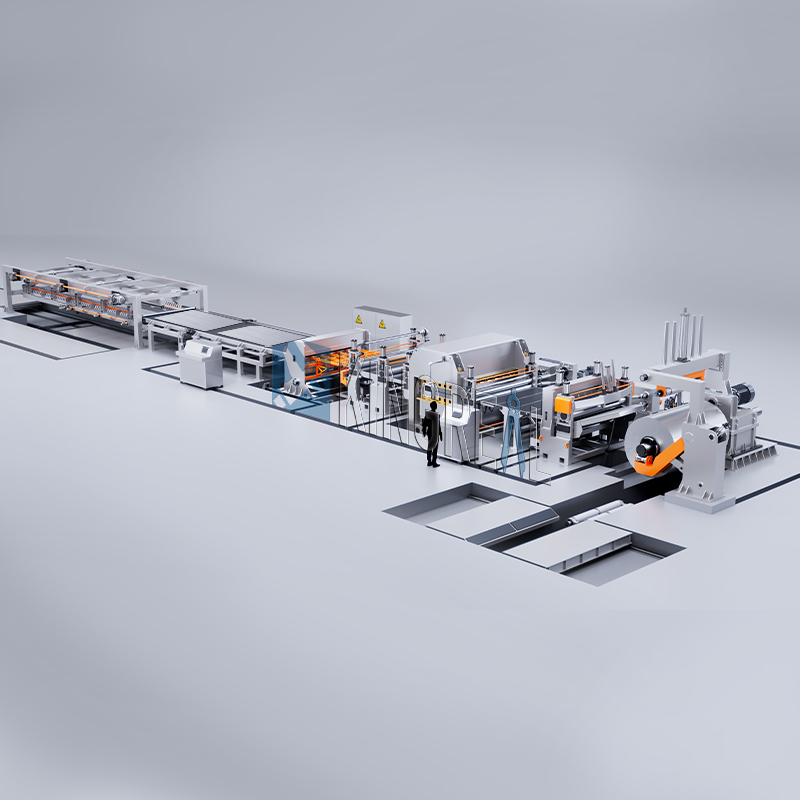

With the advent of the industrial age and the advancement of modern production technology, people have higher requirements for the efficiency and quality of automatic cut to length lines. Therefore, KINGREAL STEEL SLITTER has designed a series of fully automatic cut to length machines to meet the various needs of customers for automatic cut to length lines. In this article, KINGREAL STEEL SLITTER will give you a detailed introduction to the relevant content of the fully automatic automatic cut to length machine. I hope you can have a deeper understanding of the components and characteristics of the fully automatic automatic cut to length line. If you have the need to purchase an automatic automatic cut to length machine, welcome to consult KINGREAL STEEL SLITTER!

Automatic cut to length machines generally have the characteristics of high speed, precision, and CNC automation. They are mainly composed of feeding trolleys, auxiliary supports, decoilers, hydraulic feeders, leveling machines, limit devices, servo motor length, shearing machines, conveyor tables, pneumatic stacking, discharging workbenches, hydraulic systems and other precision components. They have main functions such as unwinding, leveling, length setting, cross-cutting, and stacking. This automatic cut to length line adopts PLC centralized control and human-machine interface display. It is an electronic control system with Mitsubishi, Yaskawa, Siemens, Baumüller, Delta, Schneider and other leading brands. Conventional processable coil thickness ranges from 0.2MM to 6MM, width ranges from 150MM to 2000MM, coil weight can reach 25T, shearing accuracy can reach ±0.5MM/M, and the maximum speed of the unit can reach 80M/min; according to the actual production needs of customers, laminating devices, trimming devices, double leveling machines, double stacking tables, etc. can also be added. Automatic cut to length machine has the characteristics of high degree of automation, good leveling quality, accurate shearing accuracy, high production efficiency, stable and reliable performance, and convenient operation and maintenance.

1) Standard, professional, high-speed steel strip material shearing processing center configuration;

2) Independent NC servo feeding and sizing device;

3) Laminating device, trimming device and other optional devices can be added;

4) Double-head or single-head hydraulic decoiler can be selected according to material weight;

5) Famous brand electronic control made in Germany and Japan can further ensure accuracy and stability;

|

Model |

Sheet thickness (mm) |

Coil width(mm) |

Leveling accuracy(mm/㎡) |

Tolerance of length(mm/m) |

Speed(m/min) |

Coil weight(Tons)max |

|

Model 1 |

0.3-2.0 |

150-650 |

1.2 |

±0.5 |

40 |

3、5 |

|

Model 2 |

0.3-2.0 |

300-850 |

1.2 |

±0.5 |

40 |

5、10 |

|

Model 3 |

0.3-2.0 |

300-1050 |

1.2 |

±0.5 |

40 |

5、10 |

|

Model 4 |

0.3-2.0 |

400-1300 |

1.2 |

±0.5 |

40 |

10、15 |

|

Model 5 |

0.3-2.0 |

400-1600 |

1.2 |

±0.5 |

40 |

15、20 |

|

Model 6 |

0.4-3.0 |

150-650 |

1.2 |

±0.5 |

40 |

3、5 |

|

Model 7 |

0.4-3.0 |

300-850 |

1.2 |

±0.5 |

40 |

5、10 |

|

Model 8 |

0.4-3.0 |

300-1050 |

1.2 |

±0.5 |

40 |

10、15 |

|

Model 9 |

0.4-3.0 |

400-1300 |

1.2 |

±0.5 |

40 |

10、15 |

|

Model 10 |

0.4-3.0 |

400-1600 |

1.2 |

±0.5 |

40 |

15、20 |

|

Model 11 |

0.5-4.0 |

400-1300 |

1.2 |

±0.5 |

40 |

10、15 |

|

Model 12 |

0.5-4.0 |

400-1600 |

1.2 |

±0.5 |

40 |

10、15 |

|

Model 13 |

0.5-4.0 |

500-2000 |

1.2 |

±0.5 |

40 |

15、20 |

|

Model 14 |

1-6 |

400-1600 | 1.5 |

±0.5 |

40 |

20、25 |

|

Model 15 |

1-6 |

500-2000 |

1.5 |

±0.5 |

40 |

20、25 |

① High efficiency

The biggest advantage of the automatic cut to length line is that it can improve production efficiency for customers. Since all components are fully automatic, labor costs can be minimized. This fully automated design allows the automatic cut to length machine to maintain efficient operation for a long time, avoiding fatigue and mistakes common in manual operation. The reduction of manpower not only reduces production costs, but also improves overall work efficiency, giving companies a stronger advantage in market competition. The automatic cut to length line will not feel tired, which means that the automatic cut to length machine can operate 24 hours a day, significantly improving production capacity. In this way, companies can complete a large number of orders in a short period of time, respond quickly to market demand, and improve customer satisfaction.

② High precision

In terms of shearing accuracy, the automatic cut to length line also performs quite well. According to the different shearing methods in the automatic cut to length machine, KINGREAL STEEL SLITTER mainly designs several distinctive automatic cut to length lines, including flying cut to length machine, swing shearing cut to length machine, rotary shearing cut to length machine and fixed shearing cut to length machine. These types of automatic cut to length lines are all controlled by PLC during the shearing process to ensure the accuracy of cutting. The user only needs to enter the length to be cut on the panel, and the system will automatically recognize and adjust it. When the metal coil reaches the specified length, the automatic cut to length machine will cut it with extremely high precision. This precision not only reduces the waste of raw materials, but also improves the qualified rate of finished products, providing a guarantee for the production process of the enterprise.

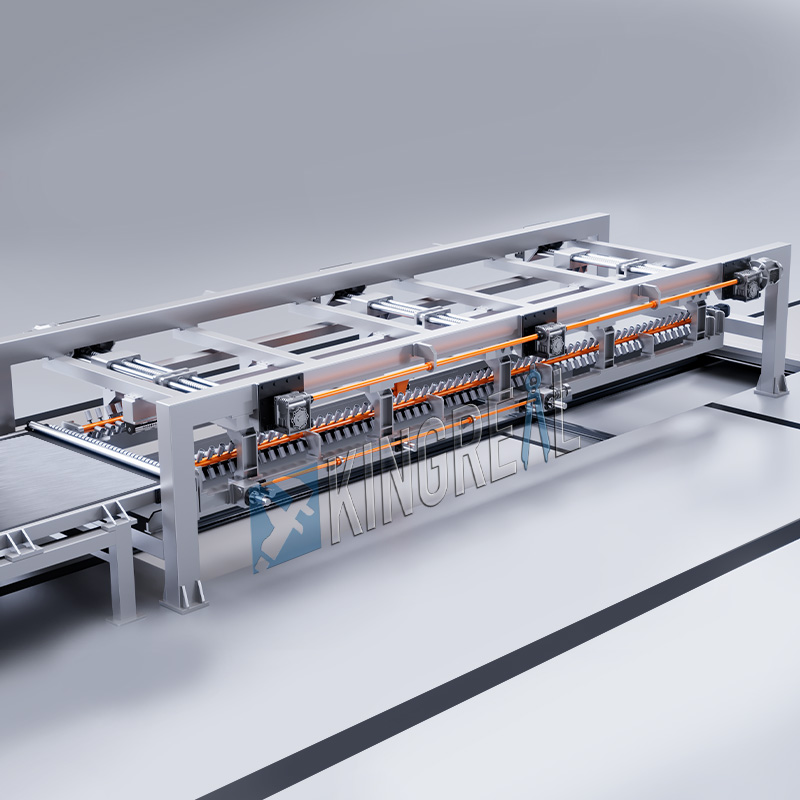

③ Provide a complete set of shearing processes

The design concept of the automatic cut to length line is not only focused on a single shearing process, but also provides a complete set of shearing processes. This process includes multiple links such as unwinding, leveling, shearing and stacking, and all steps can be completed on the same production line. This integrated design reduces the time and energy required by customers to purchase other equipment during the production process, allowing companies to focus more on their core business. Users only need to configure an automatic cut to length machine to achieve full process management from raw materials to finished products, greatly improving production efficiency and management level. At the same time, this efficient process also saves space for enterprises and reduces coordination and management costs between equipment.

④ Compatible with metal raw materials of various materials and thicknesses

The adaptability of the automatic cut to length line is also a major advantage. It can shear a variety of metal materials, including stainless steel, steel, aluminum, copper, PPGI, etc. This diversity of materials enables the automatic cut to length machine to meet the needs of different customers and adapt to the production requirements of various industries. KINGREAL STEEL SLITTER has also designed light gauge cut to length lines, medium gauge cut to length lines and heavy gauge cut to length lines, which can process metal materials with a thickness range of 0.2-20mm. If customers need to process thinner or thicker metal materials, KINGREAL STEEL SLITTER welcomes full communication with you in order to provide personalized automatic cut to length machine manufacturing solutions. Such flexibility not only enhances customers' choices, but also provides companies with coping strategies in a changing market environment.

|

|

|