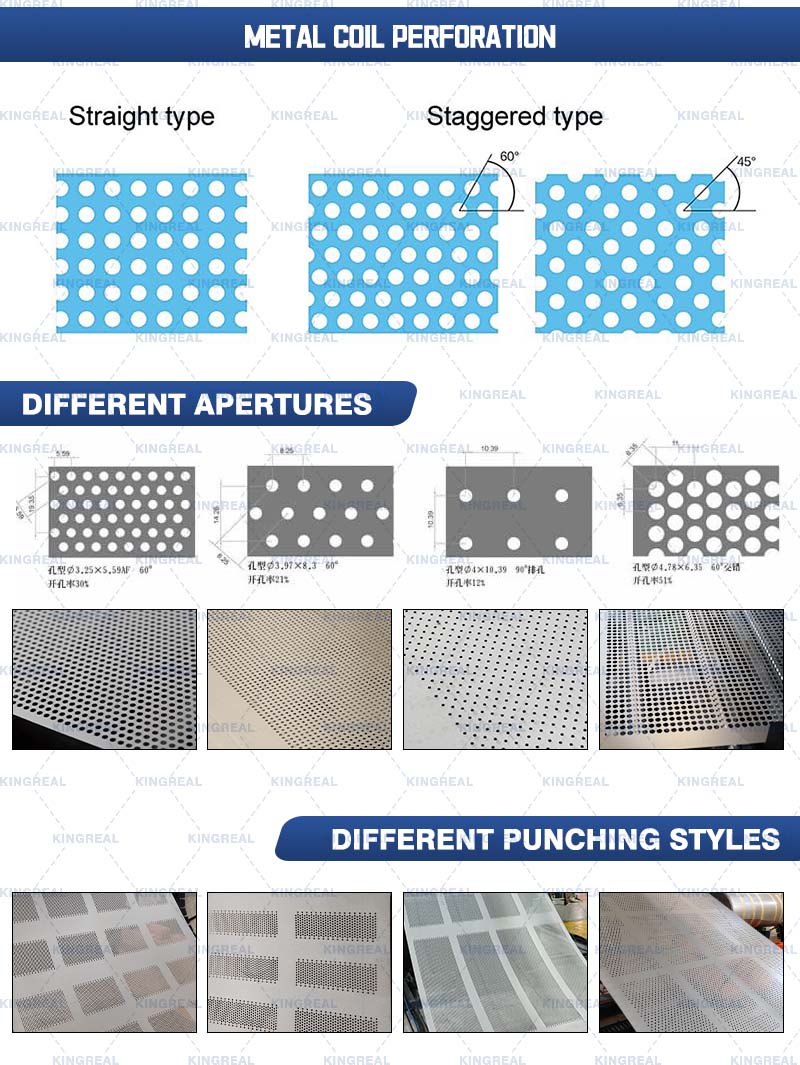

Coil Perforation Line is a perforated metal sheet that is produced by punching metal sheets through a series of processes such as punching. It is widely used in various industries. With the increasing demand for perforated plates in the market, many people also want to purchase perforated punching machines.

|

|

KINGREAL STEEL SLITTER staff have recently received many inquiries asking whether the profit of coil perforation lines is high and whether it is worth doing this industry. In this article, KINGREAL STEEL SLITTER will analyze the topic of whether coil perforation lines can bring high profits.

Coil perforation lines are widely used in many industries, including construction, home furnishing, automobiles, aviation, decoration and other fields. These industries have a stable and huge demand for punching products (such as ventilation nets, decorative panels, filter nets, sound insulation panels, etc.), especially in the following fields with high profit potential:

- Construction industry: There is a strong demand for high value-added products such as perforated aluminum plates and stainless steel decorative panels.

- Home furnishing industry: Metal furniture, speaker grilles, etc. require a large number of punching parts.

- Automobile manufacturing: The demand for precision punching products in automobile interior and exterior trims, heat dissipation nets, etc. is high.

- Industrial applications: The demand for punching products in industrial products such as filters and screens continues to grow.

Profit analysis:

Market demand is stable, especially high-end, customized punching products (such as complex patterns, special materials) have high added value and large profit margins.

The profit margin of metal punching products depends largely on the added value of the products. The following products usually have higher profits:

- High-precision products: Punching products that require strict tolerance control (such as parts used in aviation or medical fields) are sold at high prices.

- Complex design products: Products with decorative or artistic punching patterns (such as building curtain wall decorative panels) have higher added value.

- Special material products: Punching products using materials such as stainless steel, aluminum alloy, titanium alloy, etc. are sold at high prices due to high material costs.

Profit analysis:

The key to increasing profits is to produce high value-added products through technological upgrades and design innovations.

Production costs directly affect profit margins. The following aspects are key to determining costs:

- Equipment investment: Modern automated coil perforation lines require a large initial investment, but have high production efficiency and low unit costs.

- Material costs: Fluctuations in metal raw material prices have a direct impact on profits. Reasonable procurement and reduction of waste are the key to controlling costs.

- Labor costs: Punching machines with a high degree of automation can significantly reduce labor costs and reduce manual operation links.

- Energy consumption costs: Choosing energy-saving equipment helps reduce long-term operating costs.

Profit analysis:

Through equipment upgrades, optimized process flows and efficient management, production costs can be effectively reduced and profit margins can be increased.

Highly efficient production operations can significantly increase profits:

- Automated production lines: Coil perforation line with automatic feeding, automatic waste discharge and intelligent control systems can improve production speed and accuracy.

- Versatility: Coil perforation lines that can process a variety of materials, thicknesses and patterns can meet more customer needs and expand the market.

- Fast mold change: Equipment that supports fast mold change can reduce downtime and improve production efficiency.

|

|

|

Profit analysis:

Highly efficient production equipment and flexible operating models can quickly respond to market demand, thereby occupying more market share and increasing profits.

- Market competition: If there are fewer coil perforation line manufacturers in the region, competition is small and profit margins are large; conversely, if the market is saturated, profits may be compressed.

- Pricing strategy: The profit of a single product can be increased through differentiated pricing (such as providing customized services and high-end products).

Profit analysis:

In a highly competitive market, differentiation and innovation are important means to increase profits.

Providing high-quality after-sales service (such as equipment maintenance, operation training) and building brand influence can increase customer loyalty and bring more orders. Perforated punching machines from well-known brands can usually be sold at higher prices, thereby increasing profits.