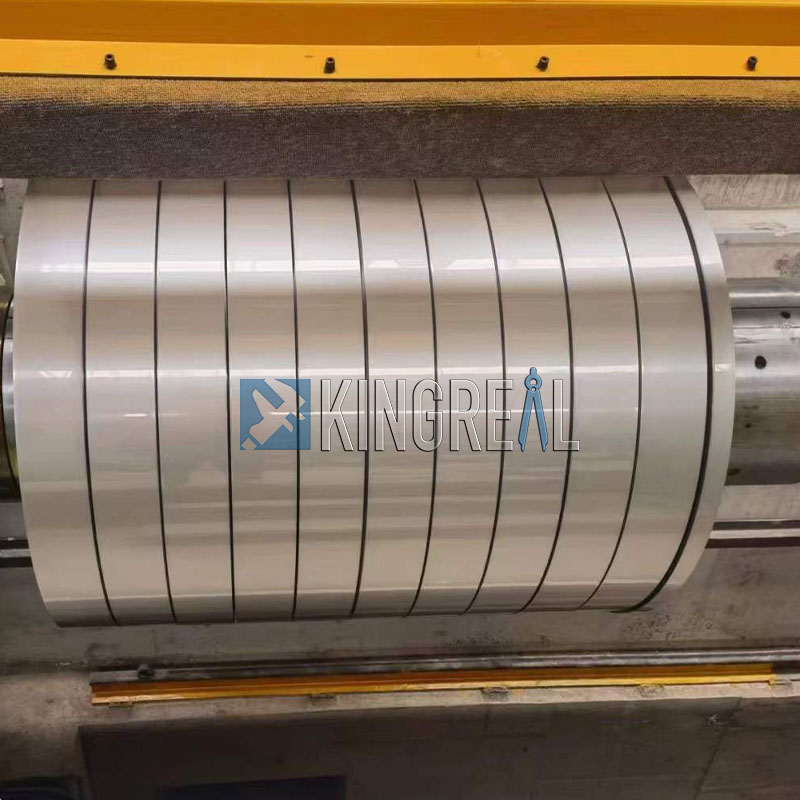

Stainless steel slitting machines are widely used to cut metal materials such as copper, stainless steel, steel, hot-rolled steel, cold-rolled steel, aluminum, and PPGI into narrow strips as required by customers. Appropriate upkeep is vital to guarantee stainless steel slitting machine runs as intended and to help to extend its lifespan. KINGREAL STEEL SLITTER in this post offers a maintenance manual for stainless steel slitting machine to enable you to properly maintain and safeguard your stainless steel slitting machine.

Regular cleaning comes first among the essential actions needed to keep stainless steel slitting machines running. Operating stainless steel slitting machines produces a lot of dust and waste that might impede their performance. You should hence often clean all components of the stainless steel slitting machine, including the blades, cutting region, and conveyor belts. Clean the stainless steel slitting machine meticulously using trustworthy cleaning tools and be cautious not to harm it.

Second, keeping stainless steel slitting machine running correctly calls for lubrication. Effective lubrication helps to minimize wear on the stainless steel slitting machine, therefore increasing efficiency by lowering friction. Follow the instructions in the equipment manual and make sure your lubrication is suitable for stainless steel slitting machines. Also, check the lubrication system often to make sure it is clean and efficient. Furthermore very important for keeping a stainless steel slitting machine is paying attention to blade wear. Stainless steel slitting machines have blades as their main components, and they have a direct bearing on cut quality and effectiveness. Check blade wear often and replace severely damaged blades right away to guarantee steady cutting performance. Pay particular note on blade alignment and calibration as well to guarantee correct performance.

Finally, keeping a stainless steel slitting machine depends in large measure on routine inspections of its electrical and control systems. Verify the connections of electrical components to guarantee their safety and dependability. Additionally confirm the operating status of the control system, encompassing button sensitivity and instrument correctness. Should any abnormalities or malfunctions be discovered, fix or replace broken components immediately to guarantee correct performance.

Following these stainless steel slitting machine maintenance instructions will help you more protect and better control your stainless steel slitting machine. Regular cleaning, lubrication, and inspection of the blades and electrical system will help extend the life of your stainless steel slitting machine, improving cutting quality and efficiency.